Problem

Possible Cause

Corrective Action

1. The crankcase-oil level is incorrect.

1. Fill or drain to the F

ULL

mark.

2. The air-cleaner element is dirty.

2. Replace.the air-cleaner element.

3. Dirt, water, or stale fuel is in the fuel

system.

3. Drain and flush the fuel system; add

fresh fuel.

4. The engine is overheated.

4. See “The engine overheats”.

5. The vent hole in the fuel-tank vent

fitting is plugged.

5. Replace the fuel cap.

The engine loses power.

6. Low compression.

6. Contact your Authorized Service

Dealer.

1. The engine-mounting bolts are loose.

1. Tighten the engine-mounting bolts.

There is abnormal vibration or noise.

2. There is a problem with the engine.

2. Contact your Authorized Service

Dealer.

The machine does not operate or is

sluggish in either direction because the

engine bogs down or stalls.

1. The parking brake is set.

1. Release the parking brake.

1. The parking brake was not released or

the parking brake is not releasing.

1. Release the parking brake or check

the linkage.

2. The transmission is broken.

2. Contact your Authorized Service

Dealer.

3. The control linkage needs adjustment

or replacement.

3. Contact your Authorized Service

Dealer.

The machine does not operate in either

direction.

4. The driveshaft or wheel-hub key has

been damaged.

4. Contact your Authorized Service

Dealer.

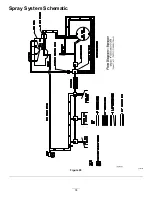

Troubleshooting the Spray System

Problem

Possible Cause

Corrective Action

1. The electrical connection on the boom

valve is dirty or disconnected.

1. Turn the valve off manually. Disconnect

the electrical connector on the valve

and clean all leads, then connect it.

2. Blown fuse.

2. Check the fuses and replace them as

necessary.

3. Pinched hose.

3. Repair or replace the hose.

4. A boom-bypass valve is improperly

adjusted.

4. Adjust the boom-bypass valves.

5. Damaged boom valve.

5. Contact your Authorized Service

Dealer.

A boom section does not spray.

6. Damaged electrical system.

6. Contact your Authorized Service

Dealer.

A boom section does not turn off.

1. The valve is damaged.

1. Disassemble the boom-section valve;

refer to the Cleaning section. Inspect

all the parts and replace any that are

damaged.

A boom valve is leaking.

1. An O-ring is deteriorated.

1. Disassemble the valve and replace

the seals using the Valve Repair

Kit; contact your Authorized Service

Dealer.

1. The boom-bypass valve is improperly

adjusted.

1. Adjust the boom-bypass valve.

2. There is an obstruction in the

boom-valve body.

2. Remove the inlet and outlet

connections to the boom valve

and remove any obstructions.

The pressure drops when you turn on a

boom.

3. A nozzle filter is damaged or clogged.

3. Remove and inspect all nozzles.

87

Содержание Multi Pro 5800-D

Страница 74: ...Spray System Schematic g034336 Figure 95 74 ...

Страница 89: ...Notes ...

Страница 90: ...Notes ...