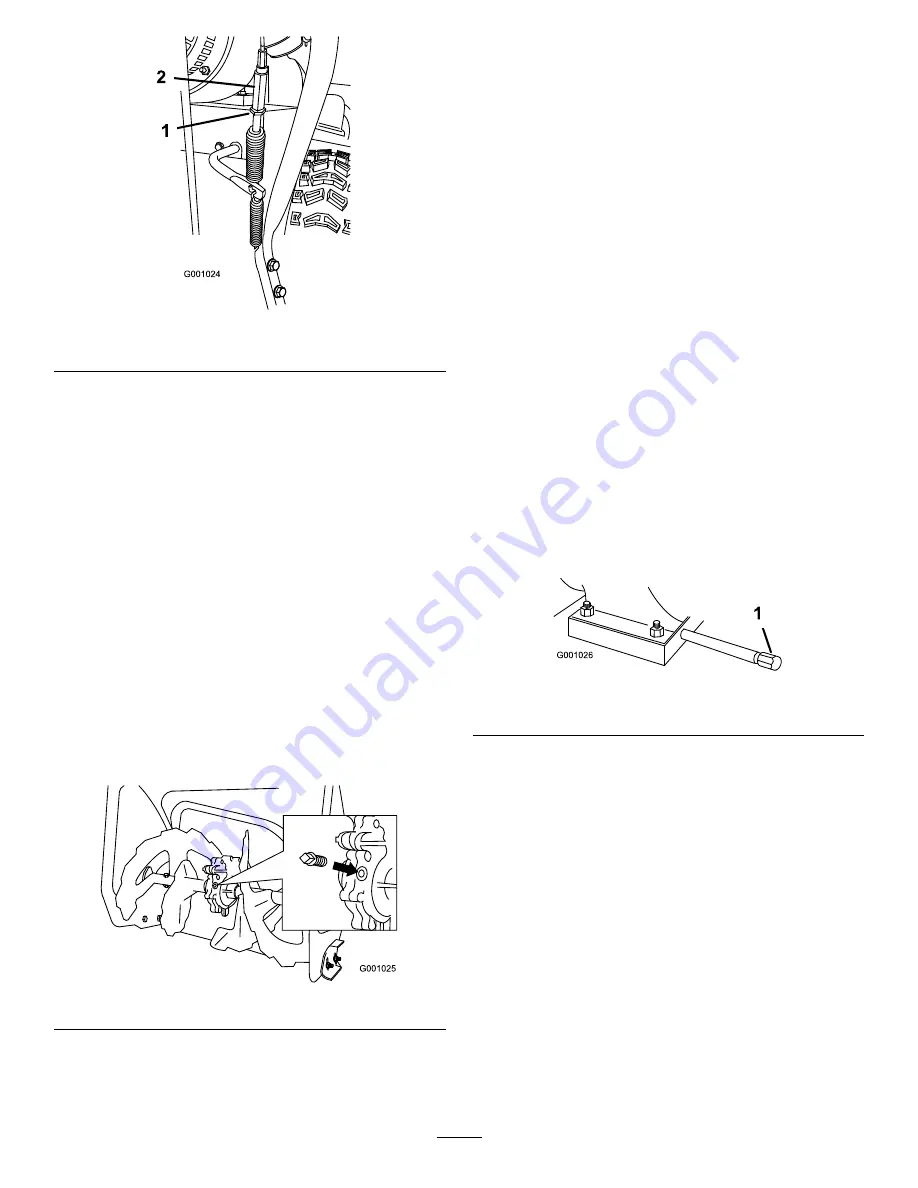

Figure 48

1.

Jam nut

2.

Turnbuckle

6. Loosen or tighten the turnbuckle that adjusts the

tension on the cable (Figure 48).

7. Adjust the turnbuckle until you obtain the proper

gap.

8. Tighten the jam nut.

9. Insert the 2 screws you previously removed on the

belt cover.

10. If the auger/impeller cable is properly adjusted but

a problem remains, contact an Authorized Service

Dealer.

Checking the Auger Gearbox

Oil Level

Service Interval:

Yearly—Check the auger gearbox oil

and add oil if necessary.

1. Move the snowthrower to a level surface.

2. Clean the area around the pipe plug (Figure 49).

Figure 49

3. Remove the pipe plug from the gearbox.

4. Check the oil level in the gearbox. The oil should be

at the point of overflowing at the filler opening.

5. If the oil level is low, add GL-5 or GL-6, SAE 85-95

EP transmission oil to the gearbox until the point

of overflow.

Note:

Do not use synthetic oil.

6. Install the pipe plug in the gearbox.

Changing the Engine Oil

Service Interval:

After the first 2 hours

Yearly

If possible, run the engine just before changing the

oil because warm oil flows better and carries more

contaminants.

Max. fill: 26 oz. (0.77 l), type: automotive detergent

oil with an API service classification of SF, SG, SH, SJ,

SL, or higher.

•

For temperatures above 32°F (0°C), use SAE 30W.

•

For temperatures between 0°F and 32°F (-18°C to

0°C), use SAE 5W30 or SAE 10W.

•

For air temperatures below 0°F (-18°C), use

SAE 0W30.

1. Clean the area around the oil drain cap (Figure 50).

Figure 50

1.

Oil drain cap

2. Slide an oil drain pan under the drain extension and

remove the oil drain cap.

3. Drain the oil.

Note:

Dispose of the used oil properly at a local

recycling center.

4. Install the oil drain cap.

5. Fill the crankcase with oil. Refer to Filling the

Engine Crankcase with Oil.

Lubricating the Hex Shaft

Service Interval:

Yearly

Lightly lubricate the hex shaft yearly with automotive

engine oil (Figure 51).

21