Servicing Air Cleaner

Service air cleaner filter every 200 hours (more fre-

quently in extreme dusty or dirty conditions).

1. Check air cleaner body for damage which could

possibly cause an air leak. Replace cleaner body if dam-

aged.

2. Release latches securing the air cleaner cover to

the air cleaner body. Separate cover from the body.

Clean inside of the air cleaner cover.

3. Gently slide filter out of the air cleaner body to re-

duce the amount of dust dislodged. Avoid knocking filter

against the air cleaner body.

4. Inspect filter and discard it if damaged. Do not wash

or reuse a damaged filter.

Washing Method

A. Prepare a solution of filter cleaner and water a

nd soak filter element about 15 minutes. Refer to

directions on filter cleaner carton for complete in-

formation.

B. After soaking the filter for 15 minutes, rinse it

with clear water. Maximum water pressure must not

exceed 40 psi to prevent damage to the filter ele-

ment. Rinse filter from the clean side to the dirty

side.

C. Dry filter element using warm, flowing air that

dose not to exceed 160_F (71_C), or allow element

to air–dry. Do not use a light bulb to dry the filter ele-

ment because damage could result.

Compressed Air Method

6. Insert new filter properly into air cleaner body. Make

sure filter is sealed properly by applying pressure to out-

er rim of filter when installing. Do not press on flexible

center of filter.

7. Reinstall cover and secure latches.

3

2

1

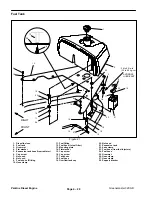

Figure 18

1. Air cleaner latches

3. Filter

2. Dust

cup

Perkins Diesel

Engine

CAUTION

Use eye protection such as goggles when

using compressed air

A. Blow compressed air from the inside to the out-

side of the dry filter element. Do not exceed 100 psi

to prevent damage to the element.

B. Keep air hose nozzle at least 2 inches (5 cm)

from the filter. Move nozzle up and down while rotat-

ing the filter element. Inspect for holes and tears by

looking through the filter toward a bright light.

5. Inspect new filter for shipping damage. Check seal-

ing end of filter. Do not install a damaged filter.

Greensmaster 3200–D

Page 4 – 13

Perkins Diesel Engine

Содержание 3200

Страница 2: ...Greensmaster 3200 3200 D ...

Страница 4: ...Greensmaster 3200 3200 D ...

Страница 6: ...Greensmaster 3200 3200 D ...

Страница 12: ...Safety Page 1 6 Greensmaster 3200 3200 D ...

Страница 14: ...Equivalents and Conversions Product Records and Maintenance Page 2 2 Greensmaster 3200 3200 D ...

Страница 17: ...Product Records and Maintenance Page 2 6 Greensmaster 3200 3200 D ...

Страница 72: ...Perkins Diesel Engine Page 4 30 Greensmaster 3200 D ...

Страница 113: ...Hydraulic System Greensmaster 3200 3200 D Page 5 41 Hydraulic System ...

Страница 161: ...Hydraulic System Greensmaster 3200 3200 D Page 5 89 Hydraulic System ...

Страница 173: ...Hydraulic System Greensmaster 3200 3200 D Page 5 101 Hydraulic System ...

Страница 234: ...Wheels and Brakes Page 7 12 Greensmaster 3200 3200 D ...

Страница 261: ...Cutting Units Greensmaster 3200 3200 D Page 8 27 Cutting Units ...

Страница 273: ......

Страница 274: ...Commercial Products FORM 96 900 SL E The Toro Company 1997 Printed in U S A ...