42

Problem

Corrective Action

Possible Causes

In the hydraulic system there is no #1

or reverse traction speed. The #2

3. The traction relief cartridge in the

#4 spool section is open.

3. Remove the relief cartridge. Repair

or replace it.

o e e se t act o speed

e

speed is normal. (continued)

4. A traction motor lacks efficiency.

There is fluid leaking past the

internal gears.

4. Test to identify the faulty motor.

Repair or replace the motor.

5. The hydraulic pump lacks

efficiency. There is fluid leaking

past the internal gears.

5. Test to verify a diagnosis. Repair or

replace the pump.

There is no traction or it is slow in all

l

i

1. The brakes are dragging.

1. Determine the cause and repair it.

selections.

2. The o-ring seals around the

traction relief cartridge or inlet

sleeve in the #4 spool valve are

faulty. Fluid is leaking by to the

tank.

2. Remove the relief and inlet sleeve.

Replace the o-rings.

3. A traction motor(s) is worn or

weak.

3. Test to verify. Repair or replace the

motor(s).

4. The pump is excessively worn.

4. Test to verify. Repair or replace the

pump.

5. The traction relief in the #4 spool

valve is open.

5. Remove, repair, or replace it.

There is no traction or it is slow in all

l

i

d

h l ff

d

1. The oil level in the reservoir is low.

1. Add oil to the proper level.

selections and the reels are affected.

2. The shift lever bracket is loose.

2. Adjust and tighten the shift lever.

3. The rear camshaft is misadjusted.

3. Adjust the camshaft.

4. The engine lacks power.

4. Repair as necessary.

The shift lever is binding.

1. The #4 spool detent assembly is

lacking lubrication.

1. Remove the valve bank.

Disassemble the detent assembly

and repair it.

All three cutting units raise and lower

too slowly.

1. The lift cylinder and linkages are

binding due to lack of lubrication.

1. Lubricate more frequently.

The center (#1) cutting unit is dropping

too late or too early.

1. The flow control valve is

misadjusted.

1. Adjust the valve.

The front cutting units are too high or

too low when they are in the raised

(transport) position.

1. The front lift cylinders are

misadjusted.

1. Adjust the cylinders.

The cutting units lift too slowly.

1. The rear camshaft is misadjusted.

1. Adjust the camshaft.

g

y

2. The #1 spool travel is restricted by

the mow/lift switch.

2. Adjust the switch.

3. The lift check poppet in the #1

spool section is stuck partially

closed.

3. Remove the lift check and repair or

replace it.

The center cutting unit (#1) reel

operates in the raised position.

1. The rear camshaft is misadjusted.

The #3 spool is too far out of the

body.

1. Adjusted the camshaft.

2. The brazed tube assembly on the

#3 spool section is restricted.

2. Remove the restriction.

3. The valve return port between the

#3 spool section and the right-hand

cover is restricted.

3. Disassembly the cover and remove

the restriction.

Содержание 04351 Greensmaster 3050

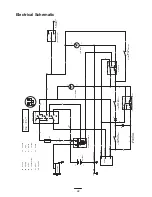

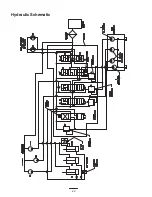

Страница 40: ...40 Hydraulic Schematic ...

Страница 46: ...46 ...