33

4.

Fill the hydraulic tank with approximately 4.5 gallons

of hydraulic oil; refer to Checking the Hydraulic

System, page 18.

5.

Start the machine and run it at idle for 3 to 5 minutes to

circulate the fluid and remove any air trapped in the

system. Stop the machine and recheck the fluid level.

6.

Dispose of the used oil properly.

Checking the Hydraulic Lines

and Hoses

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

•

Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

•

Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

•

Seek immediate medical attention if fluid is

injected into skin.

Warning

Check the hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings, weather

deterioration, and chemical deterioration. Make all

necessary repairs before operating.

Adjusting the Brakes

A brake adjustment rod is located on each side of the

machine so that the brakes can be equally adjusted. Adjust

the brakes as follows:

1.

Transport the machine and depress the brake pedal; both

wheels should lock equally.

Testing the brakes in a confined area where others

are present could cause injury.

Always check the brakes in a wide, open-spaced,

flat area which is free of other persons and

obstructions before and after adjustment.

Caution

2.

If the brakes do not lock equally, disconnect the brake

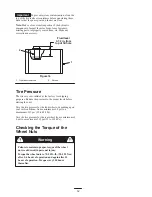

rods by removing the cotter pin and clevis pin (Fig. 43).

m–5100

1

2

3

4

Figure 43

1. Clevis pin and cotter pin

2. Jam nut

3. Clevis

4. Brake shaft

3.

Loosen the jam nut and adjust the clevis accordingly

(Fig. 43).

4.

Assemble the clevis to the brake shaft (Fig. 43).

5.

Check the amount of free travel of the brake pedal when

the adjustment is completed. There should be 1/2 to

1 in. (13 to 26 mm) travel before the brake shoes make

contact with the brake drums. Readjust, if necessary, to

achieve this setting.

6.

Transport the machine and depress the brake pedal; both

brakes should lock equally. Readjust, if necessary.

7.

It is recommended that the brakes be burnished

annually; refer to Break-In Period, page 22.

Adjusting the Rear Camshaft

A camshaft misaligned with the valve bank may cause the

following:

•

No increase in ground speed in the No. 2 (transport)

traction selection

•

The mow pedal will not stay depressed (in detent)

without foot pressure.

•

Slow lift of the cutting units

•

Slow or no drive to the cutting units

If one or more malfunctions occur, loosen the rear camshaft

mounting capscrews (Fig. 44) and relocate the cam shaft

until

the condition is corrected. Retighten the capscrews.

Important

Readjust the mow/lift switch and the lift and

mow pedal height when the camshaft adjustment is

completed.

Содержание 04351 Greensmaster 3050

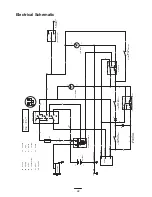

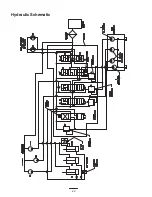

Страница 40: ...40 Hydraulic Schematic ...

Страница 46: ...46 ...