Greensmaster Flex 18/21

Traction and Reel Drive System

Page 4 – 21

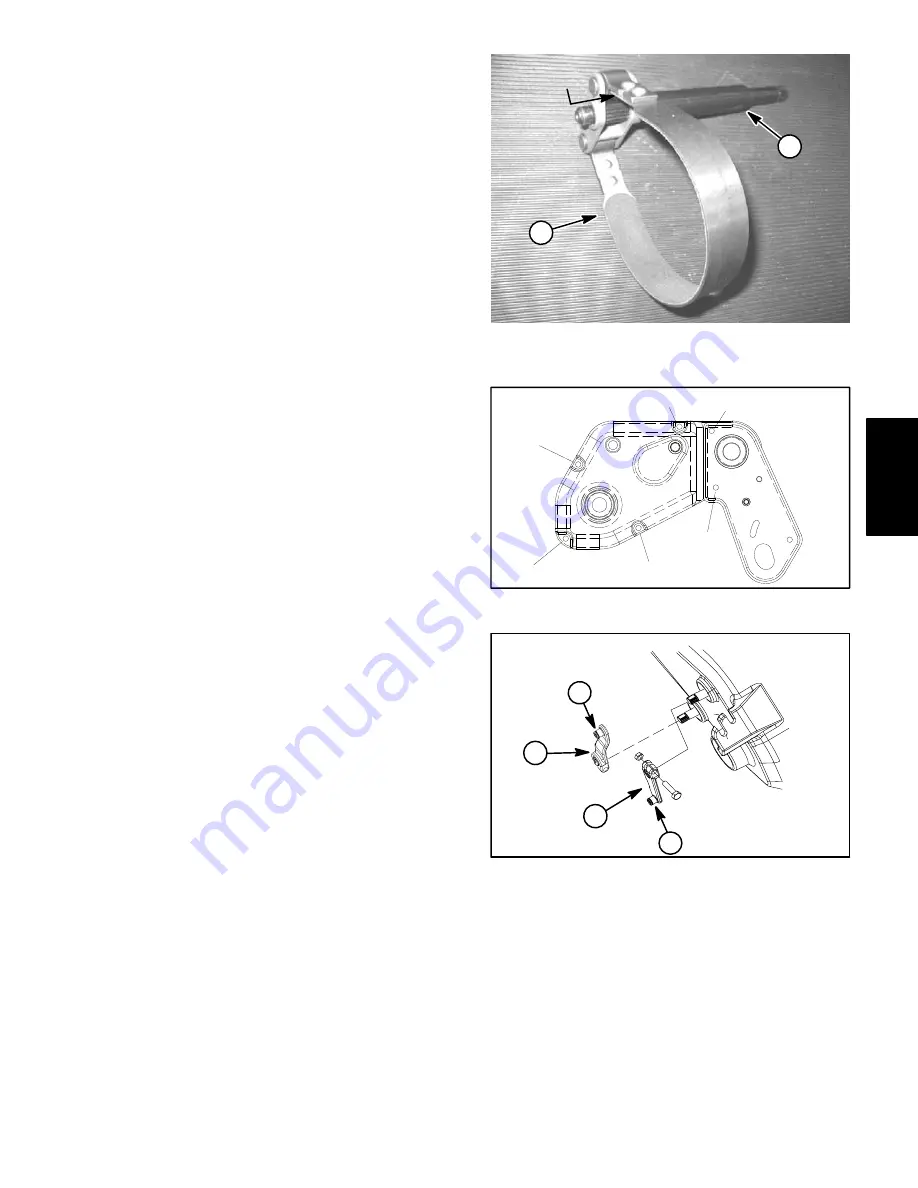

8. If traction band is replaced, the new band will have

an ink mark on the upper end of the band (Fig. 28).

9. Carefully fit traction shaft with band to the planetary

assembly and gearbox base taking care not to distort

traction band. Traction band should easily slide over

traction drum during installation. If traction band is im-

properly placed on the traction shaft or if the band is dis-

torted, it will not fit easily on the drum. Check that

planetary assembly is free to rotate with band installed.

Note: On Flex 21, if gearbox is still attached to engine,

traction lever on engine side of gearbox should be instal-

led onto traction shaft is shaft is installed into gearbox.

10.Rotate differential shaft to verify that all gears and

shafts are meshed properly.

11. Use dowel pins to position gasket to gearbox base.

12.Lubricate short differential axle shaft. Position gear-

box cover to shafts and fit cover to the gearbox base.

13.Position drive shaft plate to gearbox with three fas-

teners: two socket head screws (shorter) and one cap

screw with lock washer. Install four socket head screws

(longer) and washers in remaining holes in gearbox cov-

er. Torque gearbox fasteners from 120 to 140 in–lb

(13.6 to 15.8 N–m) in the sequence shown in Figure 29.

14.Place traction drive lever onto gearbox shaft noting

location of alignment splines on shaft and lever. Mount

traction lever with cable boss outward (Fig. 30). Secure

lever with cap screw and lock nut. Parking brake lever

installation should be done with cable attached to lever

as gearbox is being installed on machine.

15.Check gearbox operation:

A. Engage and disengage clutch, brake band and

traction band. Check for smooth engagement.

B. Turn one differential axle shaft and check that

other shaft rotates in opposite direction.

C. If smooth operation is not detected, correct prob-

lem before completing assembly.

16.Install reel drive assembly to the gearbox (Fig. 22):

A. Apply antiseize lubricant to the bore of the reel

drive pulley. Place woodruff key in gearbox shaft and

slide pulley and pulley washer onto shaft. Thread

flange nut onto shaft.

B. Position reel drive belt over pulleys and properly

tension belt (see Transmission Coupler Drive Belt

Adjustment in this section).

C. Tighten flange nut to secure pulley.

1. Traction

shaft

2. Traction

band

Figure 28

MARK LOCATION

2

1

Figure 29

3

1

4

5

2

6

1. Traction drive lever

2. Parking brake lever

3. Cable mounting boss

Figure 30

3

3

2

1

Traction and Reel

Drive System

Содержание 04022 Greensmaster Flex 21

Страница 2: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Страница 4: ...Greensmaster Flex 18 21 This page is intentionally blank ...

Страница 10: ...0 09375 Greensmaster Flex 18 21 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 28: ...Greensmaster Flex 18 21 Traction and Reel Drive System Page 4 4 This page is intentionally blank ...

Страница 48: ...Greensmaster Flex 18 21 Traction and Reel Drive System Page 4 24 This page is intentionally blank ...

Страница 58: ...Greensmaster Flex 18 21 Page 5 10 Electrical System This page is intentionally blank ...

Страница 83: ...Greensmaster Flex 18 21 Page 7 13 Cutting Unit This page is intentionally blank Cutting Unit ...

Страница 85: ...Greensmaster Flex 18 21 Page 7 15 Cutting Unit This page is intentionally blank Cutting Unit ...

Страница 111: ...Greensmaster Flex 18 21 Groomer Page 8 15 This page is intentionally blank Groomer ...