17

6. If, both in mode (MAN) as (AUTO), the signal

lamp (8) is on but the suction system does not

work, please contact the authorized technical

assistance.

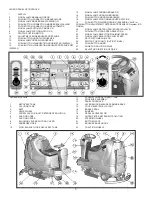

THE BRUSHES MOTOR DOES NOT WORK

1. Verify that the key switch is positioned clock-

wise to switch on the machine. In presence of

alarm signals it is necessary to switch off and on

again the machine to restore the functionality.

2. Check the charge level of the batteries on the

display (1).

3. Verify of having activated correctly the function

of washing with the brushes (see under

paragraph “STARTING OF THE MACHINE”).

4. If, both in mode (MAN) as (AUTO), the signal

lamp (18) is on but the brushes do not turn,

please contact the authorized technical

assistance.

THE TRACTION MOTOR DOES NOT WORK

1. Sit on the guiding place.

2. Verify that the key switch is positioned clock-

wise to switch on the machine. In presence of

alarm signals it is necessary to switch off and on

again the machine to restore the functionality.

3. Check the charge level of the batteries on the

display (1).

4. Check through the signal lamp (15) that the

parking brake is not inserted and eventually

release it (see under paragraph “EMERGENCY-

PARKING BRAKE”).

5. Press the accelerator pedal placed on the right

side to start the machine.

If the problem persists, please contact the autho-

rized technical assistance.

THE WATER DOES NOT COME DOWN ONTO

THE BRUSHES OR IS INSUFFICIENT

1. Verify that the key switch is positioned clock-

wise to switch on the machine.

2. Check the charge level of the batteries on the

display (1).

3. Verify of having activated correctly the function

of washing with the brushes (see under para-

graph “STARTING OF THE MACHINE”).

4. Check that the solution valve is open (see

under paragraph “FLOW ADJUSTMENT OF THE

DETERGENT SOLUTION”).

5. If, both in mode (MAN) as (AUTO), the signal

lamp (20) is on but the detergent solution does

not come down onto the brushes, it is necessary

to:

a. check the level of the liquid in the tank.

b. check that the solution filter is clean (see under

paragraph “CLEANING OF THE SOLUTION

TANK AND OF THE OUTER FILTER”).

c. check that the inner filter of the solution tank is

clean (see under paragraph “CLEANING OF THE

INNER FILTER SOLUTION TANK”).

If the problem persists, please contact the autho-

rized technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. The brushes do not have the suitable bristle

dimension: contact the authorized technical as-

sistance.

2. The brushes have got worn bristles. Check the

brushes wear condition and eventually replace

them.

To replace the brushes, see instructions under

paragraph “BRUSHES DISASSEMBLY” and

“BRUSHES AS-SEMBLY”.

3. The detergent solution is insufficient: open

more the solution valve (see under paragraph

“FLOW ADJUSTMENT OF THE DETERGENT

SOLUTION”).

4. Check that the liquid detergent is in the recom-

mended percentage.

5. Increase the brushes base pressure (see under

paragraph "ADJUSTMENT OF THE BRUSHES

PRESSURE").

Contact the authorized technical assistance for

advice.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the suction function is on and that

the recovery tank is not full.

2. Check that the squeegee rubbers are clean

(see under paragraph “SQUEEGEE CLEAN-

ING”).

3. Check the adjustment of the height and the

inclination of the squeegee (see under paragraph

“ADJUSTMENT OF THE SQUEEGEE”).

4. Check that the suction and the squeegee

hoses are correctly inserted in their proper seats

on the recovery tank.

5. Clean the suction filter (see under paragraph

“SUCTION FILTER CLEANING”).

6. Clean the squeegee hose (see under para-

graph “SQUEEGEE HOSE CLEANING”).

7. Replace the rubbers if worn out.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used.

Eventually add small quantities of anti foam liquid

into the recovery tank.

Please be aware that a bigger quantity of foam is

produced when the floor is not very dirty. In this

case please dilute detergent solution.

Содержание BR 28/27

Страница 2: ...2...

Страница 3: ...3 NOTES...