15

B. by pressing the push button (3) the manual

(MAN) functioning is chosen to start working in

manual mode and all functions have to be re-

established manually.

DAILY MAINTENANCE

ATTENTION:

All the following maintenance and cleaning

operations that refer to the following components

that are in contact with liquids and therefore:

• Solution and recovery tanks

• Solution and recovery filters

• Squeegee with their rubbers and hoses

• Brushes

must be carried out using gloves to protect from

contact with dangerous solutions.

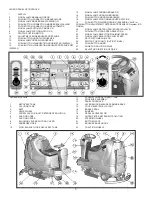

RECOVERY TANK EMPTYING AND CLEANING

1 Hold the exhaust hose (1) placed in the rear

part of the machine after having taken it off from

its fixing support.

2. Take off the plug (2) from the exhaust hose

acting upon its lever (3) and empty the recovery

tank into appropriate containers, in compliance

with the respective rules what the liquid disposal

concerns.

3. Take off suction cover (4) after rotating the

blocking levers (5).

4. Take off the filter and filter protection (6).

5. Rinse the inside of the tank with a water jet

through the hole become free of the filter, paying

attention to clean eventually also the float switch

(7) (optional) placed right under the hole.

6. Reassemble all parts.

SUCTION FILTER CLEANING

1. Take off suction cover (4) after rotating the

blocking levers (5).

2. Take off the filter (8) and its filter protection (6).

3. Clean all parts with a water jet and especially

the inside surfaces and the filter bottom.

4. Carry out cleaning operations carefully.

5. Reassemble all parts.

EMPTYING AND CLEANING OF THE

COLLECTION BOX

The machine is equipped with a collection box

for the solid dirt.

At the end of the cleaning operation it is

necessary to empty and to clean it with a water

jet.

For the emptying and the cleaning of the box:

1. Position the selector (10) for the adjustment of

the brushes pressure on position P1.

2. Start the machine (see under paragraph

“STARTING OF THE MACHINE”), automatically

the functioning mode manual (MAN) is set.

3. Activate the push button (17) of up/down of the

brushes base to lower the brushes.

4. When the brushes touch the floor and start to

turn, switch off the machine by turning the key

counterclockwise.

ATTENTION:

To carry out above operations with the electric

supply on, may cause damages to hands.

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions.

5. Unblock the bar of the right side rubber after

having released the knob (1).

6. Open the bar of the side rubber (2) as shown in

the figure.

7. Extract and carry the box by using its handles

(3).

8. Empty the box into appropriate containers, in

compliance with the respective rules what the

liquid disposal concerns.

9. Put the collection box back into its position up

to the end.

10. Place the bar of the side rubber (2) into its

position blocking it with the knob (1).

BRUSHES CLEANING

Disassemble the brushes and clean them with a

water jet (for the brushes disassembly see under

paragraph “BRUSHES DISASSEMBLY”).

ATTENTION:

To carry out brushes disassembly operations with

the electric supply on, may cause damages to

hands.

SQUEEGEE CLEANING

Keeping the squeegee clean guarantees always

the best drying result.

For its cleaning it is necessary to:

1. Take off the squeegee hose (5) from the

coupling.

2. Disassemble the squeegee (2) from its support

(1) by loosening the knobs (4) counterclockwise

and making slide the threaded parts in the

appropriate slots up to their release.

3. Clean with care the internal part of the

squeegee inlet eliminating eventual dirt residuals.

4. Clean with care the squeegee rubbers.

5. Reassemble all parts paying attention to put

the washers (3) into position, they are two for

each knob, so that they are assembled one under

and the other on each of the two slots present on

the support.

Содержание BR 28/27

Страница 2: ...2...

Страница 3: ...3 NOTES...