16

WEEKLY MAINTENANCE

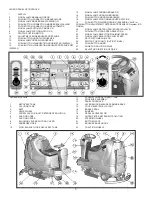

REAR SQUEEGEE RUBBER CHECK

Check the squeegee rubber wear and eventually

turn or replace it.

For the replacement it is necessary to:

1. Lift the squeegee (see under paragraph “STOP

OF THE MACHINE AFTER CLEANING

OPERATION”).

2. Release the hook (1) of the rubber holder blade

and take off the rubber.

3. Turn the rubber to a new side or replace it.

To reassemble the squeegee repeat inversely the

operations mentioned above, inserting the rubber

on the guides and blocking it with the rubber

holder blade.

SQUEEGEE HOSE CLEANING

Weekly or in case of insufficient suction, it is

necessary to check that the squeegee hose is

not obstructed. Eventually, to clean it, proceed as

follows:

1. Take off the hose (1) from the squeegee

coupling.

2. Wash the inside of the hose with a water jet.

3. To reassemble the hose repeat inversely the

above-mentioned operations.

CLEANING OF THE SOLUTION TANK AND OF

THE OUTER FILTER

1. Bring the machine to an appropriate place for

the detergent solution draining.

2. Unscrew the solution tank cap (1).

3. Unscrew the cap of the exhaust filter (2) and

take off the filter. Be careful not to lose the gasket

of the cap.

4. Open the solution valve (see under paragraph

“FLOW ADJUSTMENT OF THE DETERGENT

SOLUTION”), so that the detergent solution flows

down into appropriate containers.

5. Rinse with a water jet the solution tank and the

components of the filter.

6. Reassemble all parts.

NOTE: in case of need it is possible to wash only

the components of the outer solution filter as

above-mentioned by closing the solution valve

adjustment (see under paragraph “FLOW

ADJUSTMENT OF THE DETERGENT

SOLUTION”), so that the detergent solution

remains in the solution tank.

CHECK OF THE SIDE RUBBERS

With the brushes assembled, the side rubbers

must touch the floor. If they are worn, they have

to be replaced.

To replace the rubbers on both sides of the

machine:

1. Unblock the bar of the side rubber after having

released the knob (1).

2. Open the bar of the side rubber (2) as shown

in the figure.

3. Take off the fixing screws (3) of the rubber

blade (4) and replace the rubber.

4. Reassemble all parts.

TWO-MONTHLY MAINTENANCE

FRONT SQUEEGEE RUBBER CHECK

Check the wear of the squeegee rubber and

eventually replace it.

For the replacement it is necessary to:

1. Take off the squeegee (see under paragraph

“SQUEEGEE CLEANING”).

2. Unscrew the wing nuts in the front part of the

squeegee.

3. Take off the rubber holder blade.

4. Replace the front rubber.

5. Reassemble all parts.

SIX-MONTHLY MAINTENANCE

CLEANING OF THE INNER FILTER SOLUTION

TANK

Empty the solution tank, remove the fitting (1) of

the water outlet by taking off the two screws that

fix it to the tank in the rear part of the machine.

Clean the inside filtrating part of the fitting from

eventual dirt. Pour some water into the tank to

clean it. Reassemble the fitting onto the solution

tank.

CHECK OF THE BRAKES

Check the braking efficacy of both rear wheels.

Should the braking be insufficient, please contact

the authorized technical assistance.

TROUBLESHOOTING GUIDE

ATTENTION:

If with the key switch positioned clockwise to

switch on the machine the display and other

functions are not activated, it is necessary to

check the batteries' connection to the machine

(see under paragraph “CONNECTION

BATTERIES' CONNECTION AND SWITCHING

ON OF THE MACHINE”). If the problem persists,

please contact the authorized technical assis-

tance.

THE SUCTION MOTOR DOES NOT WORK

1. Verify that the key switch is positioned

clockwise to switch on the machine. In presence

of alarm signals it is necessary to switch off and

on again the machine to restore the functionality.

2. Check the charge level of the batteries on the

display (1).

3. Verify of having activated correctly the function

of drying (see under paragraph “STARTING OF

THE MACHINE”).

4. Check that the recovery tank is not full.

5. Check that the float switch (7) (optional) in the

recovery tank is assembled correctly.

Содержание BR 28/27

Страница 2: ...2...

Страница 3: ...3 NOTES...