125

Sharpening a Plane Iron

To get a 100 % straight edge when sharpening wide tools

such as a plane iron, you need to pay attention to a couple

of factors that influence the result. The grinding jig gives

the tool a constant edge angle towards the stone but the

shape achieved depends on how much

pressure

you apply

on the right or left side. Also the

time

you spend sharpening

on each side influences the shape.

If you press equally on both sides and move the tool evenly across the stone, you will get

a concave and not a straight edge. This is because the middle part is exposed to a longer

sharpening time than the sides. Compensate for this effect by spending more time sharpen-

ing on the sides.

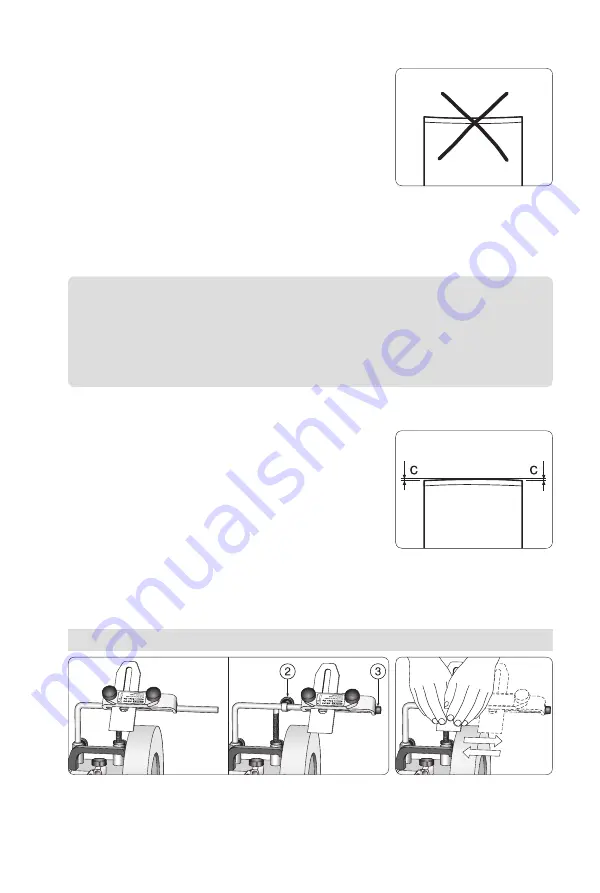

Camber Shape

Most types of plane irons should have a slight convex

shape or a camber. The degree of camber depends on

type of plane and should be approximately the same as

the thickness of the shavings. The camber (c) varies from

0.8 mm (

1/32

") for a jack plane down to 0.05 mm (0.002") for

a smooth plane. A scrub plane should have a much larger

camber, which cannot be achieved in the SE-76 jig. Use

the Tool Rest SVD-110. The camber is achieved by press-

ing harder on the sides. A longer protrusion of the blade in the jig will facilitate this effect,

as most plane irons are a bit flexible. On a thick, stiff tool you create the camber shape by

spending more time sharpening on the sides.

Setting the safety stops

First mount the inner, movable stop (2) so the tool rests with

approx. 6 mm (¼") on the stone. Then mount the outer stop (3),

which is fixed and independent of the tool width.

Move the tool continuously

between the two stops. Spend

more time sharpening the sides.

Important

Like for all Tormek jigs (except for the planer/jointer blade and

moulding knife attachments) you should keep in mind that there is no grind-

ing depth stop. This means that you decide with your hands – pressure and

grinding time – where the grinding takes place. Check the shape frequently

and grind more, where it is needed.