122

Flatten and Hone the Back of the Tools

To achieve a really sharp and durable edge, both of the two converging surfaces must be

smooth. If we sharpen and hone the bevel to perfection but the back is not equally flat and

smooth, you will never achieve a satisfactory result. On most new tools, the back has vis-

ible grooves from the manufacturing process. These should be removed and the surface

honed and polished.

Working free-hand, remove the grooves on the side of the grindstone and then hone and

polish the surface on the leather honing wheel. This work only needs to be done once, when

you start using the tool. It is a good investment in your quality tool and will last its lifetime.

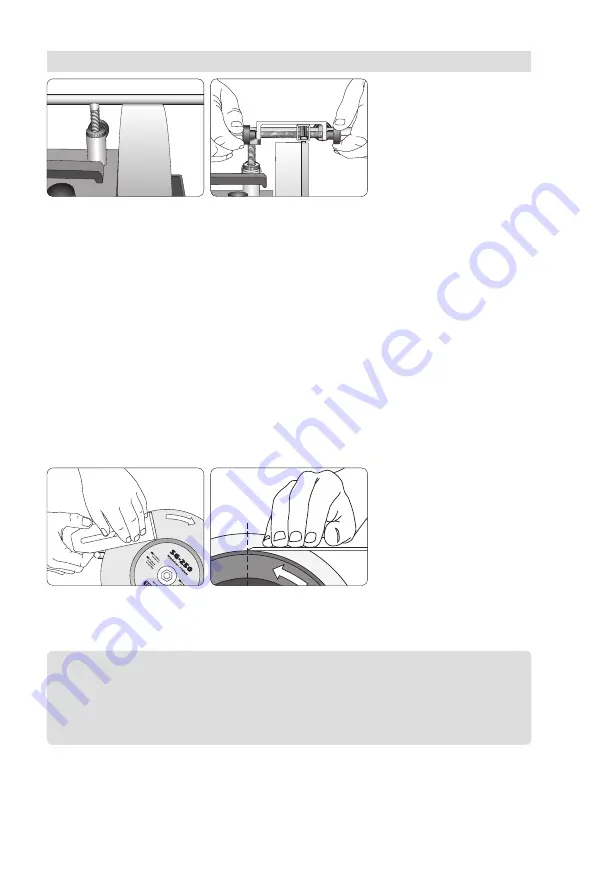

Flatten the back of the tool by

holding it flat to the grindstone

while moving it slightly.

Note

Keep the tool absolutely flat against the grindstone. Otherwise the tip

can cut into the wheel and be rounded off. Let the side of the tool rest on the

Universal Support which should be placed close to the stone as shown. You

do not need to smooth the tool more than 25–30 mm (1–1¼") from the edge.

Before you start grinding,

check that the stone is true

by letting the Universal

Support touch the stone.

If necessary, true it with

the Truing Tool TT-50 so

the surface is flat and parallel

to the Universal Support.

Preparations

Hone the back free-hand.

Hold the tool so it is a tangent

to the wheel.