TECHNICAL DOCUMENT

TORMACH.COM

Page 1

©Tormach® 2020. All rights reserved.

Specifications subject to change without notice.

TD10487_PCNC440_ATC_Install_1220A

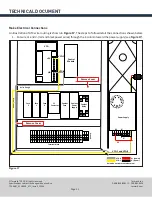

PCNC 440 AUTOMATIC TOOL CHANGER

Product Identification:

Automatic Tool Changer for PCNC 440 (PN 35900)

Purpose:

This document details the installation and use of the Automatic Tool Changer on a PCNC 440 mill.

Qty

.

PCNC 440 Automatic Tool Changer

PN

2

Adjustable Standoff Assembly

35833

1

ATC Assembly

—

1

Fixed Standoff Assembly

35832

1

PCNC 440 Coolant Relocation Bracket Kit

37260

10

Plastic Screw

32173

1

Tilt Standoff Assembly

35911

NOTE:

If any of these items are missing, contact Tormach

Customer Service at (608) 849-8381 for a replacement.

IMPORTANT!

Please read this section before you begin installing your Automatic Tool Changer (ATC).

• Power Drawbar

You must install the PCNC 440 Power Drawbar on your machine before installing the

PCNC 440 Automatic Tool Changer (ATC). Do not install the power drawbar button; tool changes are

completed with the ATC.

• PathPilot

You must update your controller to the latest version of PathPilot before installing and

operating the ATC. If you don’t, there’s a risk that the ATC could become inoperable. Follow the

instructions detailed in “Before You Begin” on page 3.