5. Reexamine the alignment of the ATC in the X direction. If the

rod isn't perpendicular to the vertical edge of the machinist's

square, repeat Steps 2 through 5.

Examine the Alignment of the Carousel Door Opening

1. Remove the tool holder from the fork, and then set it aside.

Note:

You'll need this tool later in the installation

procedure to make further alignments.

2. Power on the machine and the PathPilot controller.

a. Turn the Main Disconnect switch to

ON

on the side of the

electrical cabinet.

b. Twist out the Emergency Stop button on the operator box,

which enables movement to the machine axes and the

spindle.

c. Press the Reset button on the operator box.

d. Bring the machine out of reset and reference it.

3. Verify that the ATC is all the way forward (toward the

spindle), and then slowly move the Z-axis down (-Z) to

examine the clearance of the carousel door opening.

4. Make sure that the carousel door opening is approximately

equal to the front back and left of the spindle mounting

flange:

l

If it is, go to Step 8.

Figure 2-11: Distance between the carousel door

opening and the spindle mounting flange.

l

If it's not, go to Step 5.

5. Loosen the four socket head cap screws that secure the ATC

main assembly to the mounting bracket with a 6 mm hex

wrench.

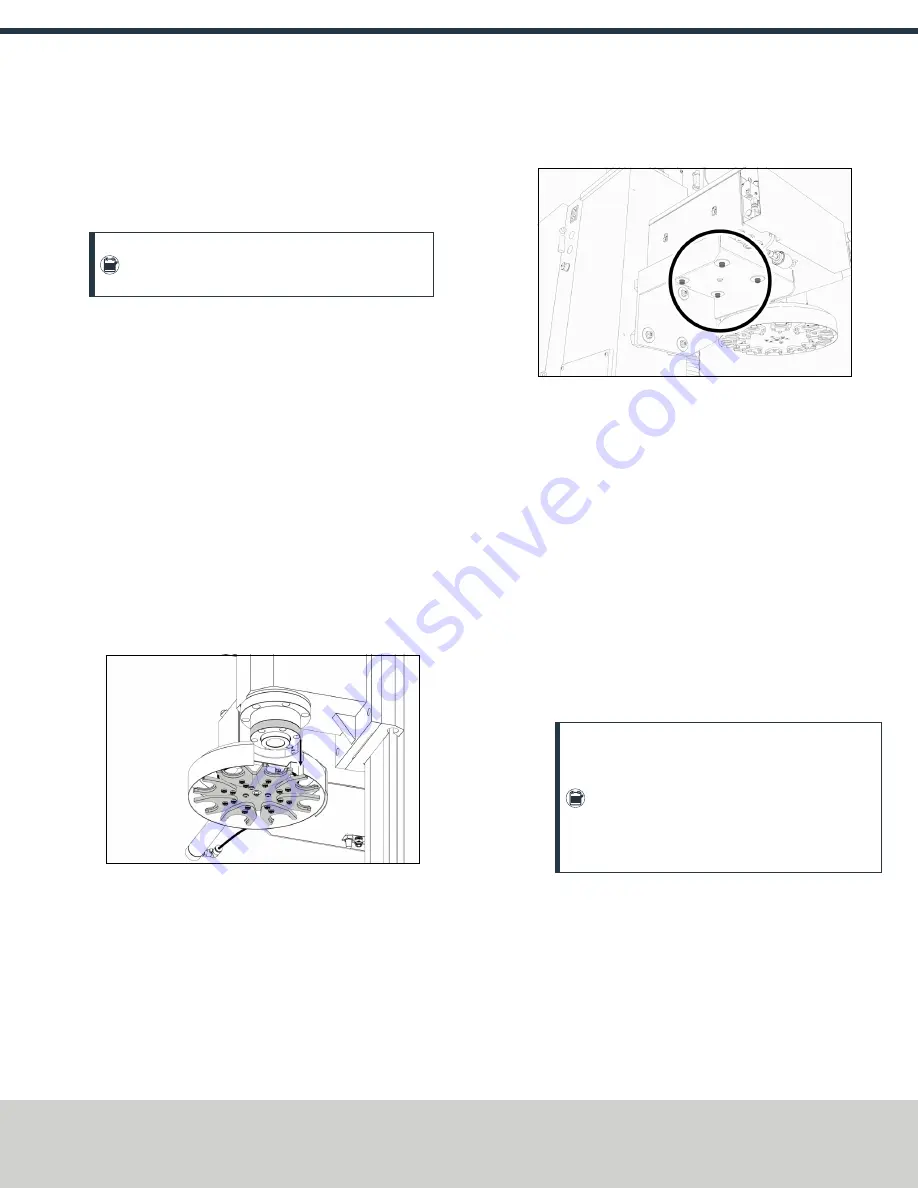

Figure 2-12: Socket head cap screws securing the ATC main

assembly to the mounting bracket.

6. Adjust the carousel door opening as required:

l

If the Carousel Door Opening is Contacting the Front

Pivot the ATC around the locating pin on the bottom of the

mounting bracket toward the front of the machine (closer

to you).

l

If the Carousel Door Opening is Contacting the Back

Pivot the ATC around the locating pin on the bottom of the

mounting bracket toward the back of the machine (closer

to the machine column).

l

If the Carousel Door Opening is Contacting the Left

Loosen the four flange nuts that attach the mounting

bracket to the column to move the bracket forward or

backward.

Note:

Moving the ATC mounting bracket could

change the position of the tilt standoff (on the Z-

column). If you move it, you must verify that the

ATC is still correctly installed; go to "Examine

Perpendicularity in the Y Direction" (on the

Repeat this step as needed.

7. Tighten the socket head cap screws and the flange nuts (if you

loosened them in Step 5).

8. Move the tool tray to its retracted position.

Page 7

©Tormach® 2019

Specifications subject to change without notice.

tormach.com

TD10627: Owner's Guide: 770MX Automatic Tool Changer (ATC) (1019A)

TECHNICAL DOCUMENT