P: 1-866-829-4411

E: [email protected]

F: 1-519-539-9191

USA: Tork Winch USA LLC

5020 Hazel Jones Road

Bossier City, LA | 71111

CANADA: Tork Winch

125 Bysham Park Drive

Woodstock, ON | N4T 1P1

TW 2000 BASKETBALL BACKSTOP WINCH

GYMNASIUM

Installation Instructions Continued >

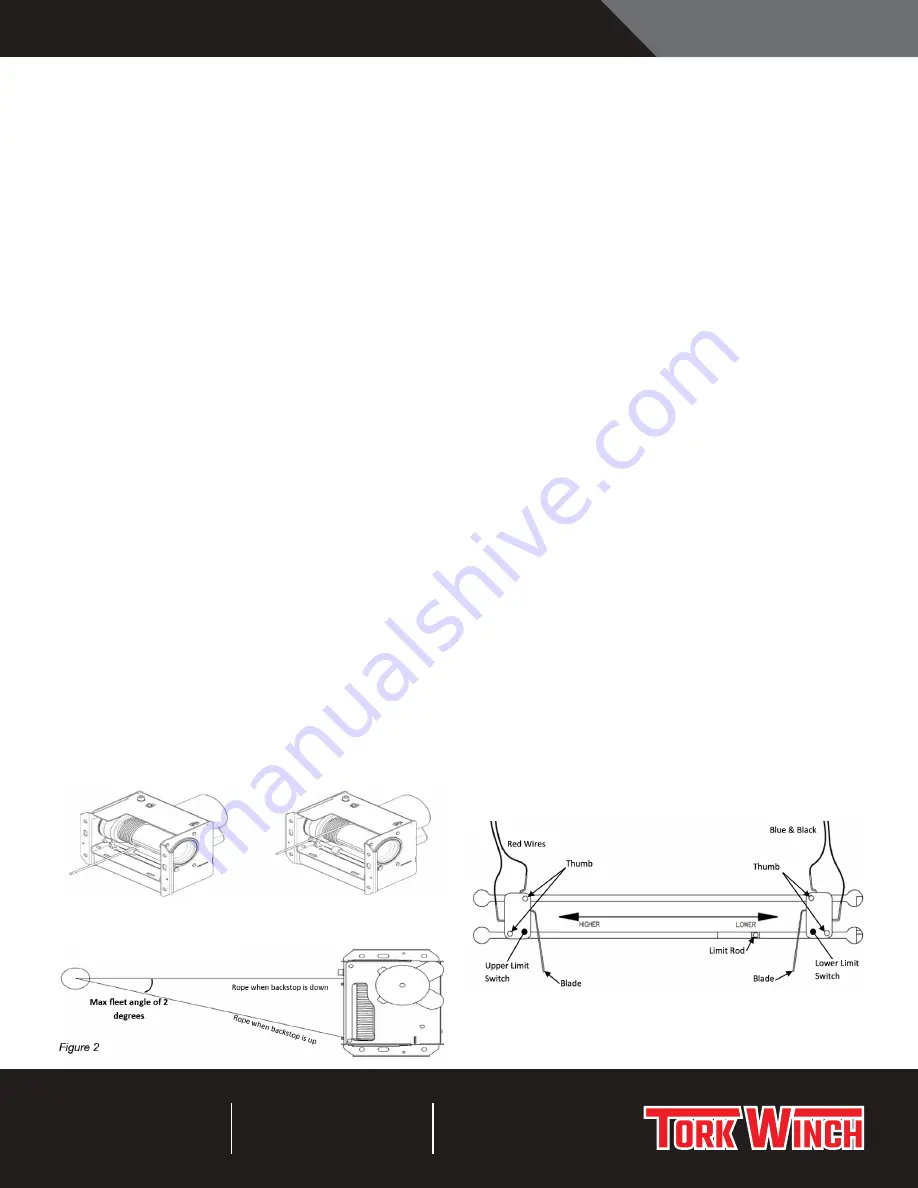

WIRE ROPE INSTALLATION (SEE FIG. 2)

The winch is designed for standard 1/4” diameter 7 x 19 aircraft

cable. The rope passes through a hole in the drum and is

prevented from pulling out by doubling the end back on itself

and securing with a standard rope clamp.

1. Manually turn the motor shaft with a ½” wrench to bring

the wire rope mounting hole in winch drum to an easily

accessible position.

2. Pass the wire rope from outside the winch in through the

rope port and then through the hole in the drum into the

center of the hollow drum. Pass enough cable through to

allow pulling of the free end.

3. Double the cable end back on itself and install the supplied

cable clamp. Tighten clamp nuts using a ½” wrench –

progressively alternating sides until clamp is fully secured.

4. Pull the rope back through the hole to bring the clamp back

tight to the hole inside the drum.

5. Running the winch in the “up” direction will begin winding

the wire rope onto the drum. Run the winch so that a

total of 3 revolutions of cable wound on the drum. These

revolutions are considered “dead wraps”- this length of

wire rope must remain on the drum at all times.

(Use extreme caution and keep hands and clothing away

from moving parts).

6. A) The cable can now be reeved over directional pulleys

and down to the mast as per the backstop manufacturer’s

recommendations. At the starting side of the drum, the

rope must exit perpendicular to the winch (0° fleet angle)

as it travels to the head pulley (see Fig. 2)

B) If no head pulley is installed in the system and the winch

is used as a direct pull; the fleet angle MUST be as close to

0° as possible when the backstop is in the fully raised position.

PLEASE NOTE:

Put only three “dead wraps” on the drum at the start of the lift.

Excessive dead wraps use space on the grooved drum-forcing

the rope onto a second layer when it is not needed.

LIMIT SWITCH ADJUSTMENT

1. Run the winch in the “up” direction to raise the backstop to

the desired (fully raised) position and stop it in this position.

Turn off the power to the winch at the breaker and remove

the electrical compartment cover. (2 hex screws)

2. Loosen the two thumb nuts holding the upper limit switch.

3. Slide the upper limit switch across until the blade contacts

the limit rod, then slide it a little further until an audible

click is heard as the switch opens. Tighten the thumb nuts.

Do not over tighten thumb nuts as this may crack the

limit switches.

The top limit is now set.

4. Temporarily reinstall the cover and run the backstop down

to the desired lower stop position. Set the lower limit

switch the same way.

5. Run the backstop up and down again to ensure that the

limit positions are set correctly. Note: The wire rope should

not be under a slack condition when the backstop is in the

lower position.

6. Make a final check to make sure that all fasteners are

tight and the rope is tracking properly in the drum grooves

before putting the winch into use.

PLEASE NOTE:

One upper and one lower travel limit switch is provided. Proper

adjustment is simple and quick with the following procedure.

Always shut power off from the winch when working inside the

electrical compartment. The cover has been designed for quick

removal to simplify limit switch adjustment.

INSTALLATION INSTRUCTIONS

Rope must be wound on the drum

in this direction.

Rope wound in wrong direction.

Front pulley should be aligned with the motor side of the winch drum.