16

MAINTENANCE AND INSPECTION

△

!

WARNING

;

・

To operate the hoist safely, it is necessary to inspect the hoist regularly.

When the hoist is in use, obey the regulations in the crane safety standards

and perform the following inspections.

★

DAILY INSPECTION

1.

Inspection of Air pressure and Oil.

Confirm that the hoist is operating between 0.4-0.6 MPa air pressure. Also make

sure the line oiler is operating correctly. If oil does not get to the motor, this will

lead to early wear of the motor parts.

2.

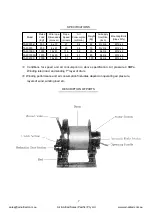

Inspection of the Wire Rope

Check the wire rope for the following;

Is the wire rope lubricated.

Is there signs of rust on the wire rope.

Are there any strands broken.

If the wire rope is not lubricated properly, this will lead to premature wear of the

wire.

3.

Does the Air Winch operate smoothly without abnormal sounds?

Stop the Air Winch if you hear any abnormal sounds when the Air Winch is

operating.

★

MONTHLY INSPECTION

1.

Check the wire rope

Check the wire rope for damage or broken strands. If a problem is seen, the wire

rope should be replaced.

2.

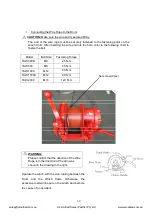

Check Operation of the brake.

Check the operation of the brake. If

the rated load slowly moves down,

the operation of the Air Winch should

be stopped and the Brake adjustment

screw should be adjusted clockwise.

If it is not possible to adjust, the brake

band has worn out and it is necessary

to change this part.

Air & Allied Sales (Pacific) Pty Ltd

www.air-allied.com.au