4

3. Transport and Storage

Transport and storage should be carried out at temperatures between -20 and 65

°

C.

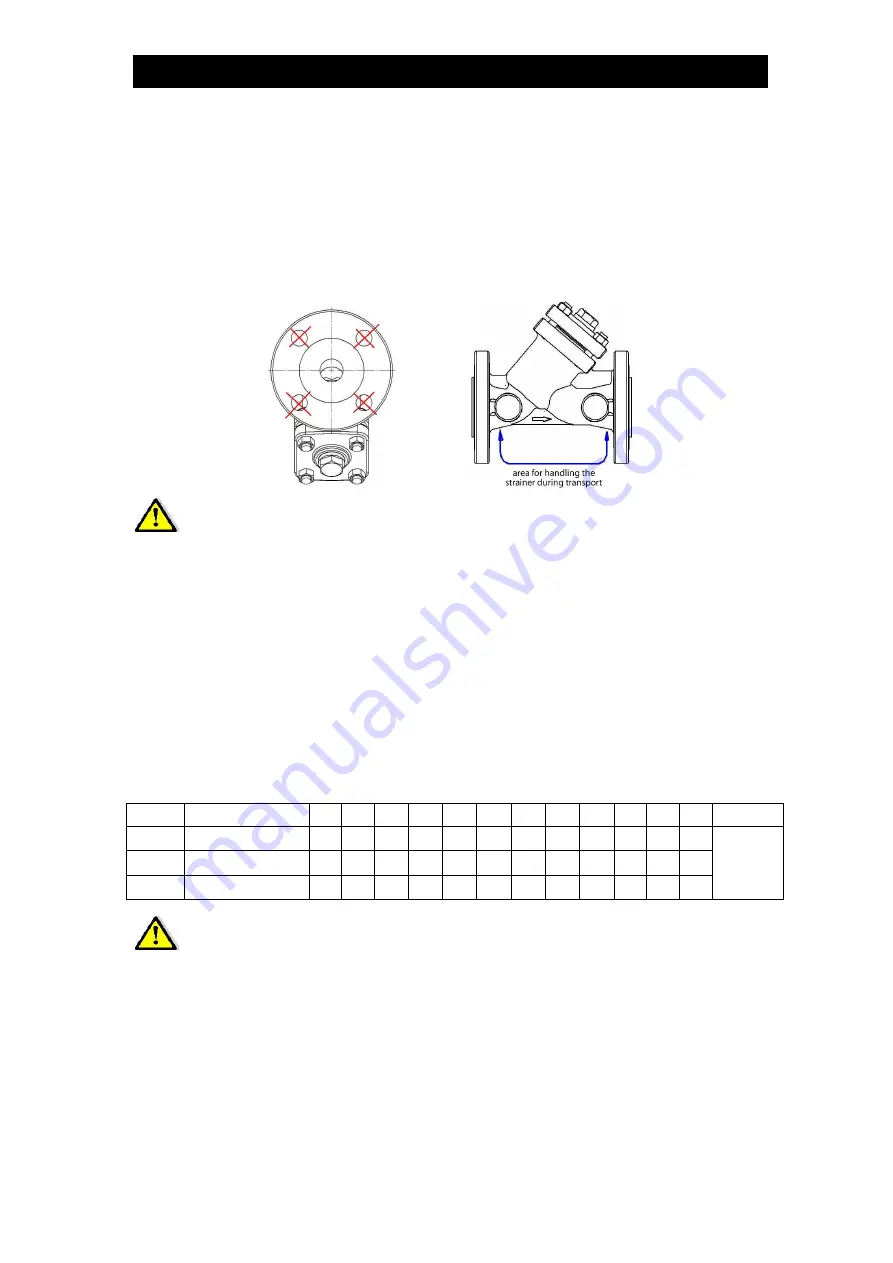

Strainers should be protected against the influence of external forces and destruction of

the paint layer as well. The aim of the paint layer is to protect the strainers against rust

during transport and storage. Strainers should be kept in clean, dry rooms and protected

against the influence of atmospheric conditions. A drying agent or heating should be

applied in damp rooms to prevent condensate formation. Strainer weights are indicated

on the relevant specification data sheet (SDS).

Do not fit lifting devices to connecting holes.

4. Function

Strainers are designed to remove solid particles from the medium flowing through them.

Their task is to protect the most sensitive plant components such as pumps, control

valves, flow and heat meters from debris. The strainer will remove solid particles which

are larger than the size of the holes in the screen mesh. In order to remove magnetic

debris from the medium it is recommended to use a magnetic cartridge located in the

centre of the filter screen. The type of working medium may make some materials

unsuitable for use. Strainers are designed for normal working conditions.

Working pressure should be adapted to the maximum temperature of the medium

according to the table below:

Model Material PN

-20

-10

50

100 120 150 200 250 300

350

400

Temp.

(

°

C)

Y8F-16

EN-GJL-250

16 --- 16 16 16 16 14.4 12.8 11.2 9.6 --- ---

Y8F-25

EN-GJS-400-18-LT 25 --- 25 25 25 25 24.3 23 21.8 20 17.5 ---

Y8F-40 GP240GH

40 30 40 40 37.1 36.3 35.2 33.3 30.4 26.7 25.7 23.8

Maximum

Operating

Pressure

(barg)

The plant designer is responsible for selecting a strainer that is suitable for working

conditions.

5. Application

・

Steam, water, air and other fluids*

(*Do not use for toxic, flammable or otherwise hazardous fluids.)

・

Industrial technologies, power industry, heat industry, HVAC plants, etc.

TEG-Y8F-M-00 20 August 2013