172-65393MA-03 (SS1VG) 4 Aug 2015

8

The Need for a Pressure-balancing Line

In principle, drain traps automatically and continuously discharge condensate that

flows in. However, air or gas caught in the piping or trap body may obstruct

condensate flow. This phenomenon is called “air binding”. Air binding occurs more

often in piping with long horizontal lengths, smaller diameters or multiple bends. To

prevent air binding and ensure air or gas can be displaced by incoming condensate,

a pressure-balancing line should be installed between the trap cover and the dry

portion of the receiver tank.

Since the SS1VG is installed vertically, a balancing line is not generally required.

However, to prevent air binding, follow the instructions below, using inlet piping with

a minimum nominal diameter of 15 mm (

1

/

2

in).

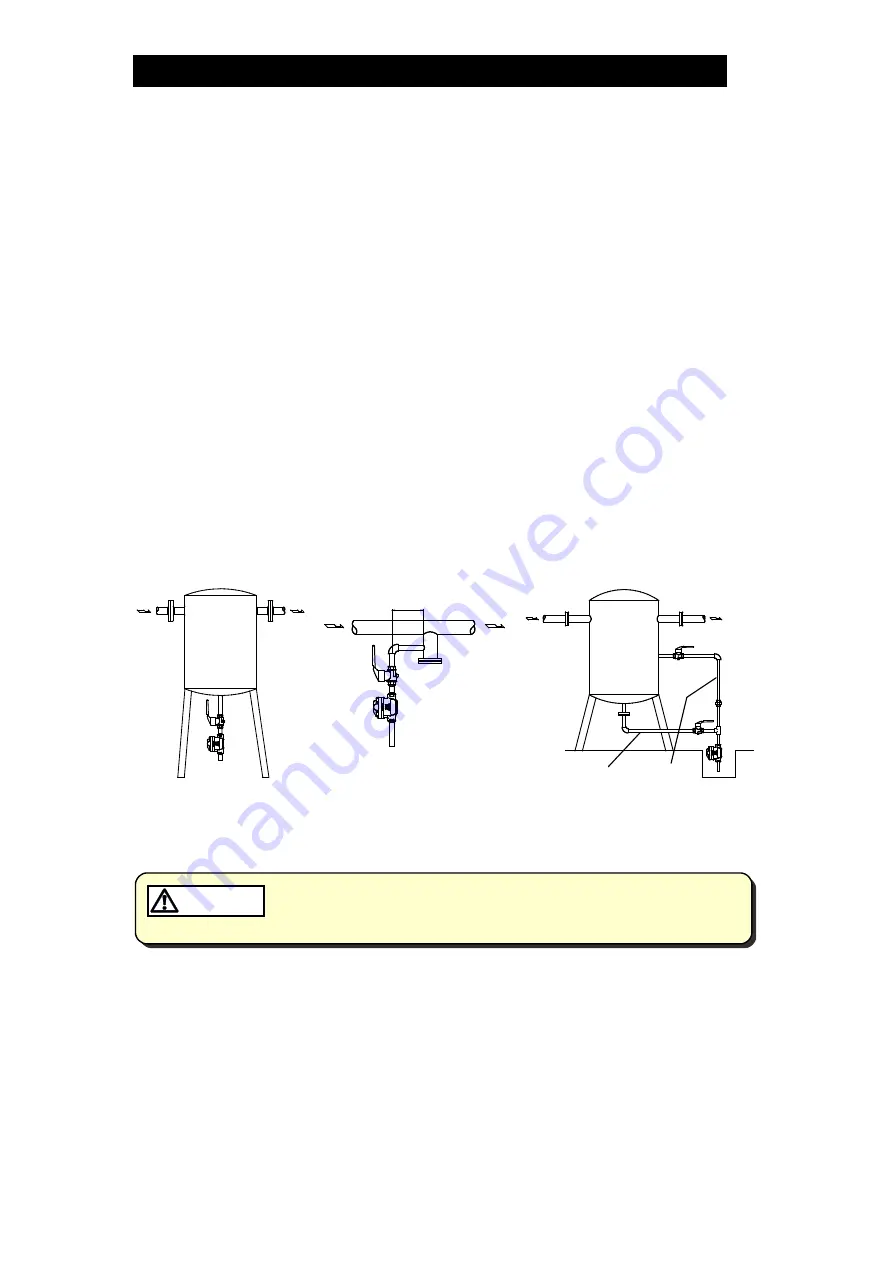

1) The inlet piping must be straight, vertical and as short as possible (see fig. 1).

2) If the point of condensate discharge requires horizontal piping, it should be

kept as short as possible, no more than 200 mm (8 in) long, then arrange

vertical inlet piping (see fig. 2).

3) If a longer horizontal length of piping is unavoidable, then a pressure-

balancing line must be installed (see fig. 3).

Figure 1

Figure 2

Figure 3

Receiver Tank

Air Main

Receiver Tank

200 mm (8 in) or less

Secondary Side Precautions

Take measures to ensure the proper handling, such as recovery or

dilution, of hazardous fluids discharged at product outlets. Outflow of

fluid or fluid leaks may lead to hazards such as flammable conditions or

corrosion, which may result in injury, fires, damage or other accidents.

CAUTION

Be sure to take precautions on the secondary side when using flammable, toxic or

other hazardous gases.

Sample precautionary procedures:

1. Flare method

2. Collection in a seal pot

3. Collection in a sealed container

Pressure-

balancing

Line

Inlet

Piping