172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

12

(3) Pressure Reducing Valve on the Motive Medium Supply Piping:

When the motive medium pressure [Pm] is greater than 0.5 MPaG (75 psig, 5

barg), install a TLV pressure reducing valve (such as the DR20) in order to reduce

the motive medium pressure to the PowerTrap. In order to prevent the pressure

from rising at dead end shut off, be sure to install a relief valve between the

pressure reducing valve and the PowerTrap.

The pressure setting on the pressure reducing valve should be between 0.05 and

0.15 MPa (7 and 20 psi, 0.5 and 1.5 bar) higher than the back pressure [Pb].

When the pumping capacity of the PowerTrap is insufficient for the set motive

pressure, increase this set pressure even further.

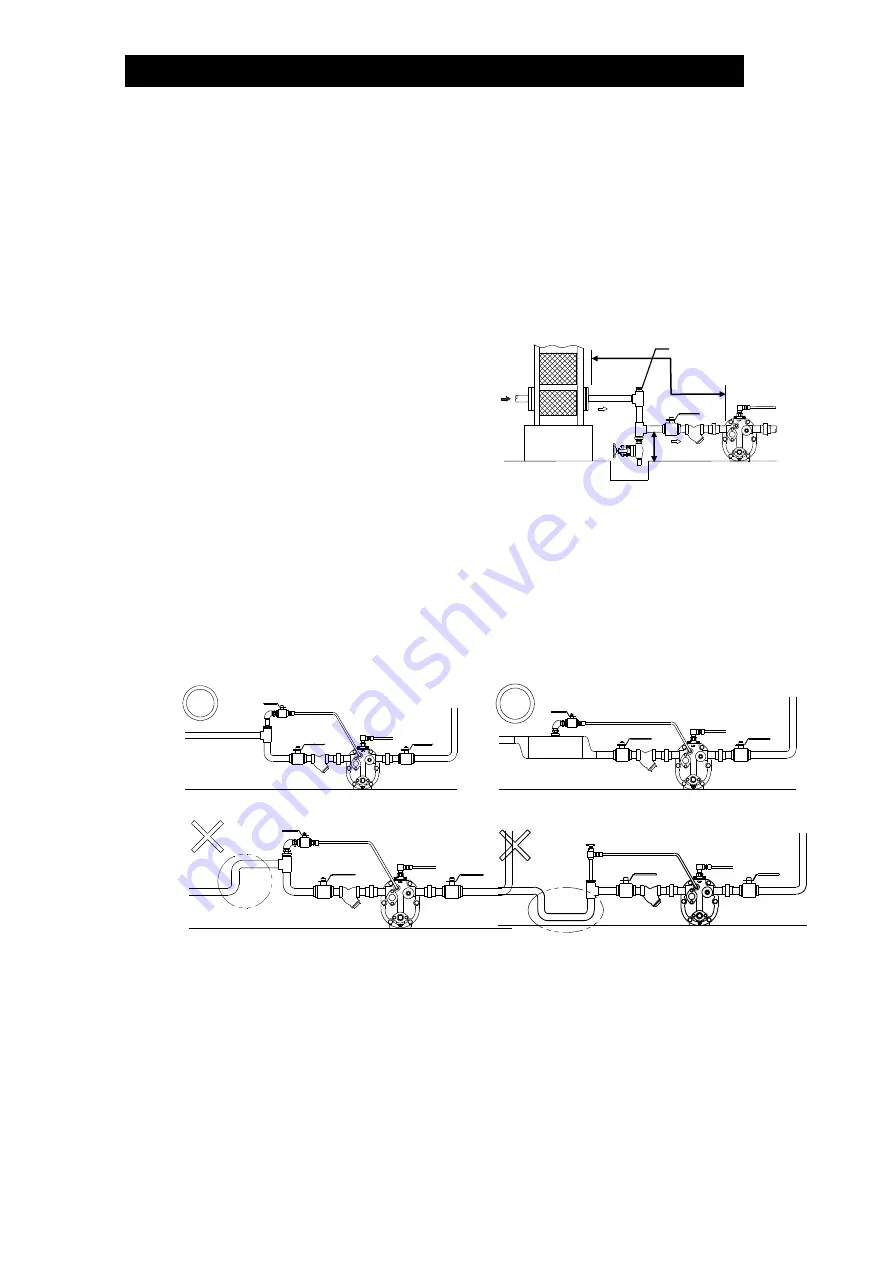

(4) Inlet and Outlet Piping

Install condensate inlet pipe [Si] to help

condensate flow into the PowerTrap by

gravity. Even if the exhaust tube is not

used (see drawing to the right), use a tee

so that the exhaust tube can be

connected when needed. The pipe

thickness should be schedule 40 or less

for proper operation.

Install a condensate inlet strainer [Ki] (40-mesh or finer) on the PowerTrap pumped

medium inlet pipe and install a union joint for maintenance. The installation should

be in a location that allows sufficient space for maintenance of the strainer [Ki].

Condensate outlet pipe [So] diameter should be at least 25 mm (1

”).

Refer to

“Sizing the Condensate Reservoir Pipe” at the end of this section for the

size of condensate inlet pipe [Si] (length of Dh).

During pumping operation, the PowerTrap uses the motive medium supply

pressure to push out the condensate in the trap. The GT5C can discharge

approximately 1.4 liters (

3

/

8

US Gallons) of pumped medium for each discharge

operation. The amount of time required for each discharge operation will be

between 5 and 30 seconds, depending on the back pressure and the motive

medium pressure. This means that the instantaneous flow through the condensate

outlet pipe [So] during the discharge operation is between 170 kg (370 lb) and 1

metric ton (2200 lb) per hour.

Flow meters must not be installed on the condensate outlet pipe [So]. Install a

steam flow meter at the equipment inlet if necessary.

Tee with Plug

Correct

Correct

Incorrect

Incorrect

Dh

Si

Filling head [A]