5

The pipeline where the valve is fitted should be arranged in such a way that

the valve body is not subjected to any bending or stretching forces.

Bolted joints on the pipeline must not cause additional stress resulting from

excessive tightening, and fastener materials must comply with the working

conditions of the plant,

・

The valve stem should be protected during pipeline painting.

・

The valve can be installed in any position, however it is recommended to install it

with the handwheel upwards.

Take note of the medium flow direction, marked with an arrow on the body.

Flow direction is established by the followings rules:

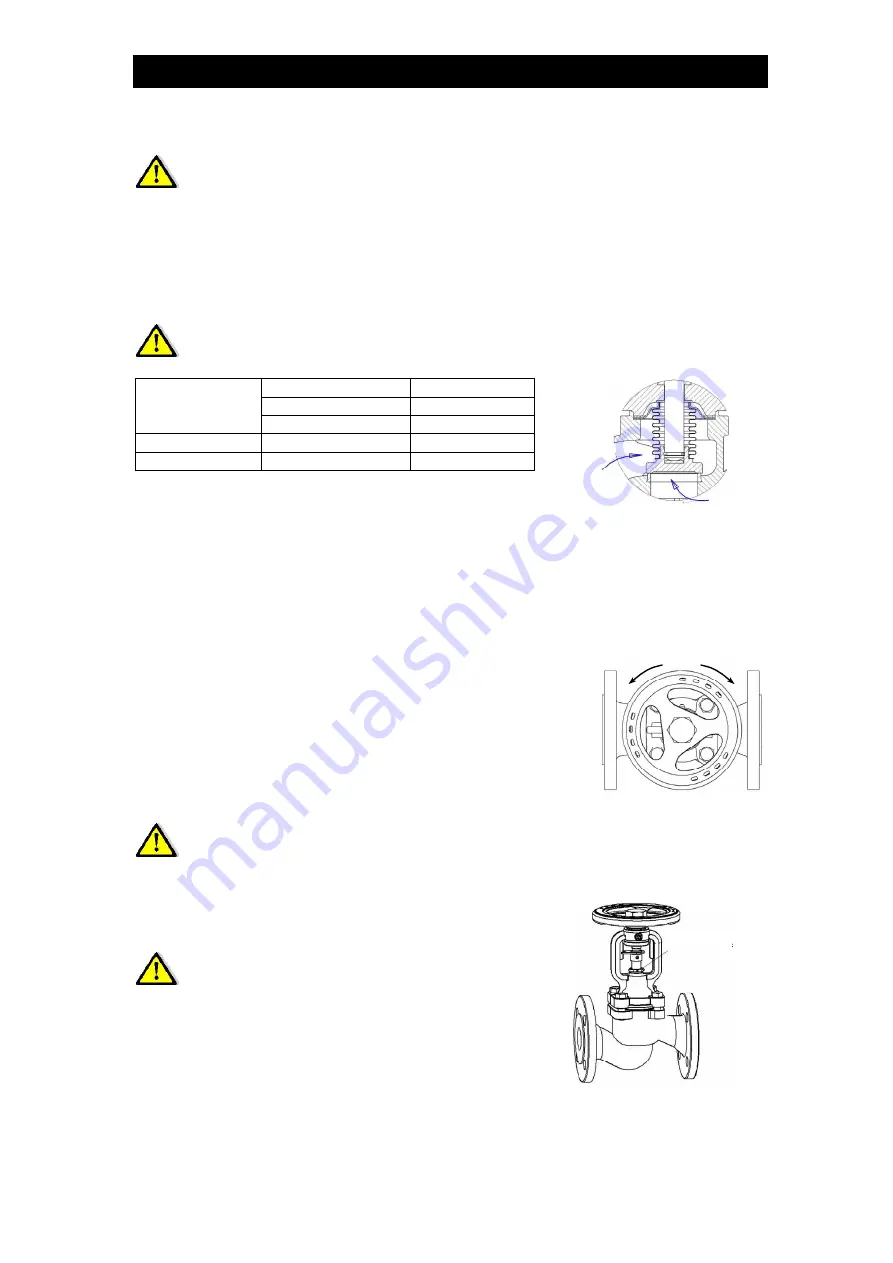

BE8H-16 / BE8H-25

BE8H-40

Stop valve

Stop valve

PN16 – PN25

PN40

Under the disc

DN15 – DN150

DN15 – DN100

On the disc

DN200 DN125

–

DN150

・

Before plant startup, especially after repairs are

carried out, flush out the pipeline through the fully

open valve, in order to discharge solid particles or

Flow under the

disc

Flow on the

disc

welding splinters which may be harmful for sealing surfaces.

・

A strainer (wire mesh filter) installed before the valve increases the certainty of

correct operation.

8. Maintenance

open

shut off

During maintenance the following rules should be observed:

・

Startup process – Sudden changes of pressure and

temperature should be avoided when starting the plant.

・

The valve is closed by turning the handwheel clockwise

when looking down from above the handwheel (according

to the arrow direction marked on the handwheel).

・

The valve is opened by turning the handwheel

counter-clockwise.

Do not use any additional lever when turning the handwheel

・

The performance of fitted valves can be checked by repeated closing and opening.

・

If leakage occurs from the valve stem, it is necessary

to tighten gland nut compressing the gland seal with

moderate force until the leakage stops.

Tighten the nut

Tighten the nut

Leakage on the gland means that the bellows

has been damaged.

The upper part of the valve should be

replaced immediately

TEG-BE8H-M-00 20 August 2013