7. Loosen and remove the three motor mounting screws.

8. Pull the motor out of the gearbox housing.

9. Inspect the armature gear on the end of the motor for

damage or excessive wear. If this gear is completely

worn out, replace the front end bell assembly.

10. Remove and inspect the 1st stage gear and 2nd stage

gear assemblies for damage or excessive wear. Replace,

if necessary.

11. Remove and inspect the front gear box assembly for

damage or excessive wear. If damaged or worn, replace

the front gear box assembly.

12. Install the motor into the gearbox housing. Make sure the

housing gasket is positioned properly.

13. Secure the motor with the three motor mounting screws.

14. Reconnect the wires to the electronic control assembly

(refer to the electrical schematic in the Parts List section

of this manual).

15. Position the electronic cover over the electronic control

assembly. Secure the electronic cover with the three

electronic cover screws.

16. Slip the baffle assembly up and around the motor. Secure

the baffle assembly with the tie wrap.

17. Slide the motor shroud over the motor. Make sure the

shroud gasket is positioned properly.

18. Secure the motor shroud with the four motor shroud

screws.

Replacing the Transducer

1. Perform the Pressure Relief Procedure, and unplug the unit.

2. Turn the pressure control knob to the CLEAN position in

the red zone to discharge any stored electricity.

3. Loosen and remove the four motor shroud screws.

Remove the motor shroud.

4. At the electronic control assembly, disconnect the black

wire coming from the transducer.

5. Pull the grommet out of the mounting plate and slide it up

the shaft of the transducer until it is clear of the mounting

plate.

6. Using a wrench, loosen and remove the transducer from

the filter housing. Carefully thread the transducer wire out

through the mounting plate.

7. Slide the grommet off of the old transducer and onto the

new transducer.

8. Thread the new transducer wire through the mounting

plate and up to the electronic control assembly.

9. Thread the new transducer into the filter housing and

tighten securely with a wrench.

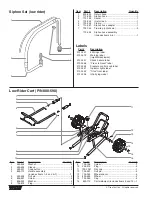

Front End Bell

Assembly

Armature Gear

1st Stage Gear

2nd Stage Gear

Front Gear Box

Assembly

Housing

Gasket

Shroud

Gasket

NOTE: Clean and refill the gear box cavity up to the rear

face of each gear with Lubriplate (P/N 314-171).

10. Push the grommet into the mounting plate.

11. Connect the transducer wire to the electronic control

assembly (refer to the electrical schematic in the Parts List

section of this manual).

12. Slide the motor shroud over the motor. Make sure the

shroud gasket is positioned properly.

13. Secure the motor shroud with the four motor shroud

screws.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 800-915.

1. Push the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the filter block. Tighten securely

with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the filter block using the dowel pin.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

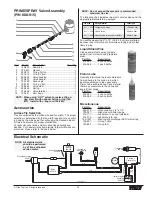

Gasket

Dowel Pin

Cam Base

Valve Stem

Filter

Housing

Valve Housing

Assembly

Valve

Handle

Groove Pin

Motor Shroud

Transducer

Grommet

Motor Shroud Screws

Electronic Control

Assembly

Mounting Plate

To Filter

NOTE: Make sure the o-ring on the transducer is in

place before threading the transducer into the

filter housing.

© Titan Tool Inc. All rights reserved.

9