© Titan Tool Inc. All rights reserved.

19

Before proceeding, follow the “Pressure Relief Procedure”

in the Operation section of this manual. Additionally,

follow all other warnings to reduce the risk of an injection

injury, injury from moving parts or electric shock. Always

unplug the sprayer before servicing!

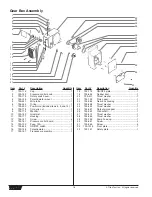

Replacing the Gear

1. Remove the safety plate (33).

2. Remove the outlet mounting bolt from the rear of the

pump (refer to the Filter Block Assembly parts list).

3. Remove the head cap screws with a 3/16" hex wrench.

(refer to the Fluid Section Assembly parts list).

4. Slide the fluid section from the crank and slide connecting

rod assembly (refer to the Fluid Section Assembly parts

list). If the fluid section will not slide off, use a screwdriver

to pry the fluid section down, then slide it off.

5. Remove the front plate (32).

6. Using a 3/16" hex wrench, remove the four screws (30)

that secure the pump housing (29) to the gearbox housing

(22).

7. Slide the pump housing (29) off the gear box housing

(22).

8. Inspect the gears beginning with the crankshaft (26),

followed by the output pinion gear (25)and the pinion gear

(21).

9. Inspect the pinion gear (21) on the motor by removing the

motor as described in the “Replacing the Motor”

procedure.

10. Reassemble by reversing the above order. When

reassembling, make sure that all washers are in place and

that the gears and bearing are properly lubricated.

11. Grease the crankshaft (26) every 100 hours. The grease

fitting is located under the front plate (32).

12. Grease the crank and slide connecting rod assembly

every 100 hours (refer to the Fluid Section Assembly parts

list). The grease fitting is located on the crank and slide

connecting rod assembly under the front plate (32).

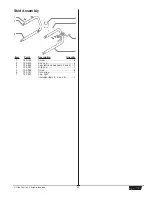

Replacing the ON/OFF Switch

1. Remove the four screws (12) that secure the pressure

control board (13) to the gear box housing. Remove the

pressure control board.

2. Disconnect the two black wires from the ON/OFF Switch

(15).

3. Using a wrench, remove the rubber boot (19) and the

ON/OFF plate (18).

4. Remove the ON/OFF switch (15).

5. Install a new ON/OFF switch (15) and reattach the

ON/OFF plate (18) and rubber boot (19). Tighten securely.

6. Reconnect the two black wires to the new ON/OFF Switch

(15).

7. Reinstall the pressure control board (13) and secure in

position using the four screws (12).

Replacing the Power Cord

1. Remove the four screws (12) that secure the pressure

control board (13) to the gear box housing. Remove the

pressure control board.

2. Disconnect the power cord (7) from the ON/OFF switch

(15), the pressure control board (13), and the grounding

screw (refer to the electrical schematic).

3. Loosen the cord grip housing (11) and remove the power

cord (7).

4. Install the new cord in the reverse order of disassembly.

5. Reinstall the pressure control board (13) and secure in

position using the four screws (12).

WARNING

Pressure Switch Replacement

1. Remove old pressure switch. Be sure all loose parts are

removed from the electrical box in the gear box housing

(22).

2. Install the transducer assembly (17) with o-rings in place.

Then press the assembly securely into the filter block. It

is recommended that you replace the polyethylene gasket

that is between the pump and the filter block.

3. Reattach the filter block by guiding the transducer wires

through the bottom hole of the electrical box in the gear

box housing (22). Reinstall the two original bolts that

mount the filter block to the pump. Be sure to tighten

them evenly.

5. When installing the plastic potentiometer mount (4), from

the top of the electrical box, be sure the stop (raised

portion of the mount) is closest to the opening of the

electrical box. Square up the mount to the opening. Use

a rubber mallet to press the mount onto the pump, making

it flush. Loctite is supplied for mounting.

6. Put the potentiometer shaft (16), through the upper hole

in the electrical box, from the inside. The wires on the

potentiometer should come out of the box. Turn the

potentiometer, clockwise or counterclockwise until it finds

the locating hole and stops turning. Install the rotary

switch seal (3), onto the shaft of the potentiometer. Use a

needle nose pliers to start the nut, and with a 1/2” socket

1/4” drive, tighten to a torque of 4 inch-lbs.

7. Turn the potentiometer shaft (16) clockwise until it stops.

8. Loosen the nut on pressure control knob (2), and install

onto the shaft of the potentiometer (16) with the pointer

pointing away from the opening of the electrical box.

9. Hand tighten the nut onto the pressure control knob (2)

and turn the knob clockwise until it hits the stop. With a

5/16” socket, tighten the nut onto the knob to 2 inch-lbs.

Install the plastic cap (1) onto the top of the knob.

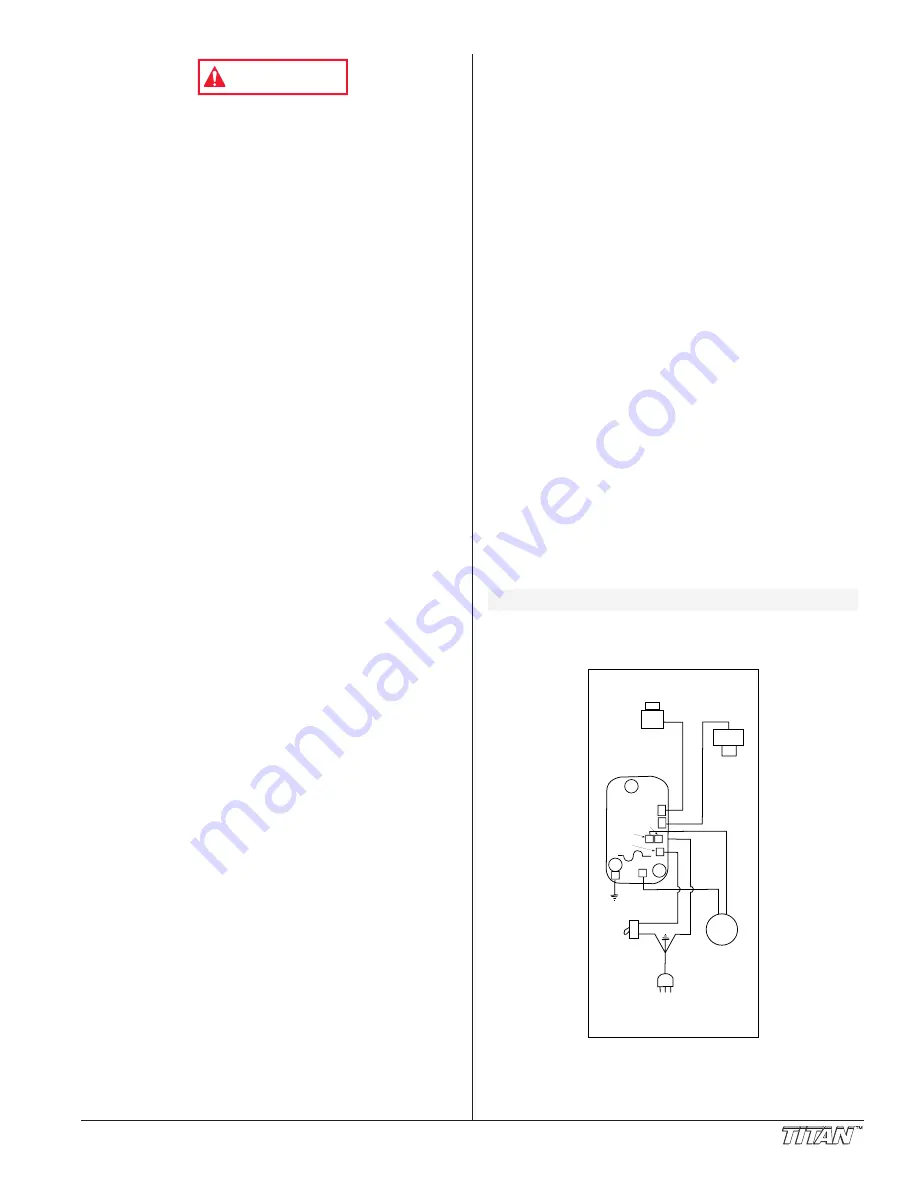

Electrical Schematic

TRANSDUCER

700-197

POTENTIOMETER

700-158

PRESSURE

CONTROL

BOARD

440HP-- 700-161

447HPX -- 700-162

SWITCH

MOTOR

PLUG

BLACK

BLACK

WHITE

WHITE

J5

NEUT

J6

SWITCH

J7

MOTOR

J8

GND

J3

J2

J4

MOTOR

ELECTRICAL CONTROL ASSEMBLY

110V -- 440; 550

NOTE: Do not over-tighten the nut on the potentiometer.