TIMBERWOLF

TW 190TDHB

23

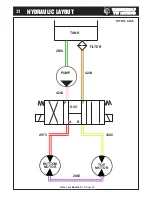

All the hydraulic hoses should be regularly inspected for chafing and leaks. The hydraulic system is

pressurized to 150 Bar (2175 PSI) and thus the equipment containing it must be kept in good condition.

Identify the hoses that run to the top motor. These have the highest chance of damage as they are

constantly moving. If any hydraulic components are changed new seals should be installed during

reassembly. Fittings should then be retightened.

GREASING ROTOR BEARINGS

ENGINE SERVICING

CHECK HOSES

Both front and rear bearings are sealed and do not need greasing.

All engine servicing must be performed in accordance with the Engine Manufacturer’s Handbook

provided with the machine.

FAILURE TO ADHERE TO THIS MAY INVALIDATE WARRANTY AND/OR

SHORTEN ENGINE LIFE.

SERVICE INSTRUCTIONS

Содержание TW 190TDHB

Страница 26: ...TIMBERWOLF TW 190TDHB 25 CERTIFICATE OF CONFORMITY...

Страница 27: ...26 EXAMPLE IDENTIFICATION PLATE TIMBERWOLF TW 190TDHB...

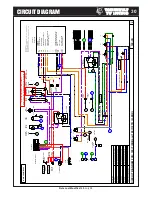

Страница 30: ...TIMBERWOLF TW 190TDHB 29 ELECTRICAL PARTS LOCATOR Date Last Modified 19th Sept 05...

Страница 34: ...blank page...