21

SERVICE INSTRUCTIONS

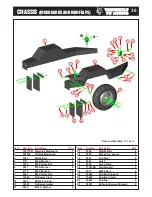

TENSION DRIVE BELTS

WARNING

Use plastic gloves to keep oil off skin and dispose of the used oil

and filter in an ecologically sound way. The oil and filter should be

changed once a year or at any time it becomes contaminated.

Before starting check that the chipper is standing level and brush

away loose chips.

2

1

3

4

A

1.

Remove the near side roller box guard.

2.

Open the rotor housing.

3.

Slacken the four 24 mm nuts that retain the

roller box (bolt is retained underneath).

4.

Slacken the lock nuts on the belt tension bracket.

5.

Turn appropriate lock nut to move roller box in

desired direction. Take care to keep roller box

square. Slightly tighten nut A (see diagram)

when tension is near desired amount. Continue

to tension belts until correct tension is achieved.

For instructions on checking belt tension

& correct belt tension values, please refer

to the Timberwolf V-Belt Tensioning Data

Table at the end of the manual

.

6.

When the belt tension is correct tighten

the four 24 mm roller box retaining nuts.

7.

Tighten the lock nuts.

8.

Grease the roller box slides and rollers.

9.

Close the rotor housing and fasten securely.

10.

Refit the near side roller box guard.

NOTE: There will normally be a rapid drop in tension during run-in period for new belts. When new

belts are fitted, check the tension every 2 - 3 hours and adjust until the tension remains constant.

Belt failures due to lack of correct tensioning will not be covered under your Timberwolf warranty.

1.

Remove the black screw cap from the top of the filter housing.

2.

Partially remove filter element from inner cup. Leave filter to

drain for 15 minutes.

3.

Remove filter element from cup when clear of hydraulic oil.

4.

Remove drain plug and drain oil into a suitable container.

5.

Replace drain plug.

6.

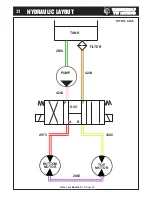

Refill with vG 32 hydraulic oil until the level is between the min and

max lines marked on the tank (about 40 litres).

7.

Refit the filter cup, install a new filter element and refit the

black screw cap, to the filter housing, ensuring o-ring remains

in place.

2

4

1

CHANGE HYDRAULIC OIL AND FILTER

TIMBERWOLF

TW 190TDHB

Содержание TW 190TDHB

Страница 26: ...TIMBERWOLF TW 190TDHB 25 CERTIFICATE OF CONFORMITY...

Страница 27: ...26 EXAMPLE IDENTIFICATION PLATE TIMBERWOLF TW 190TDHB...

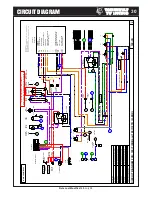

Страница 30: ...TIMBERWOLF TW 190TDHB 29 ELECTRICAL PARTS LOCATOR Date Last Modified 19th Sept 05...

Страница 34: ...blank page...