13

Chapter 5

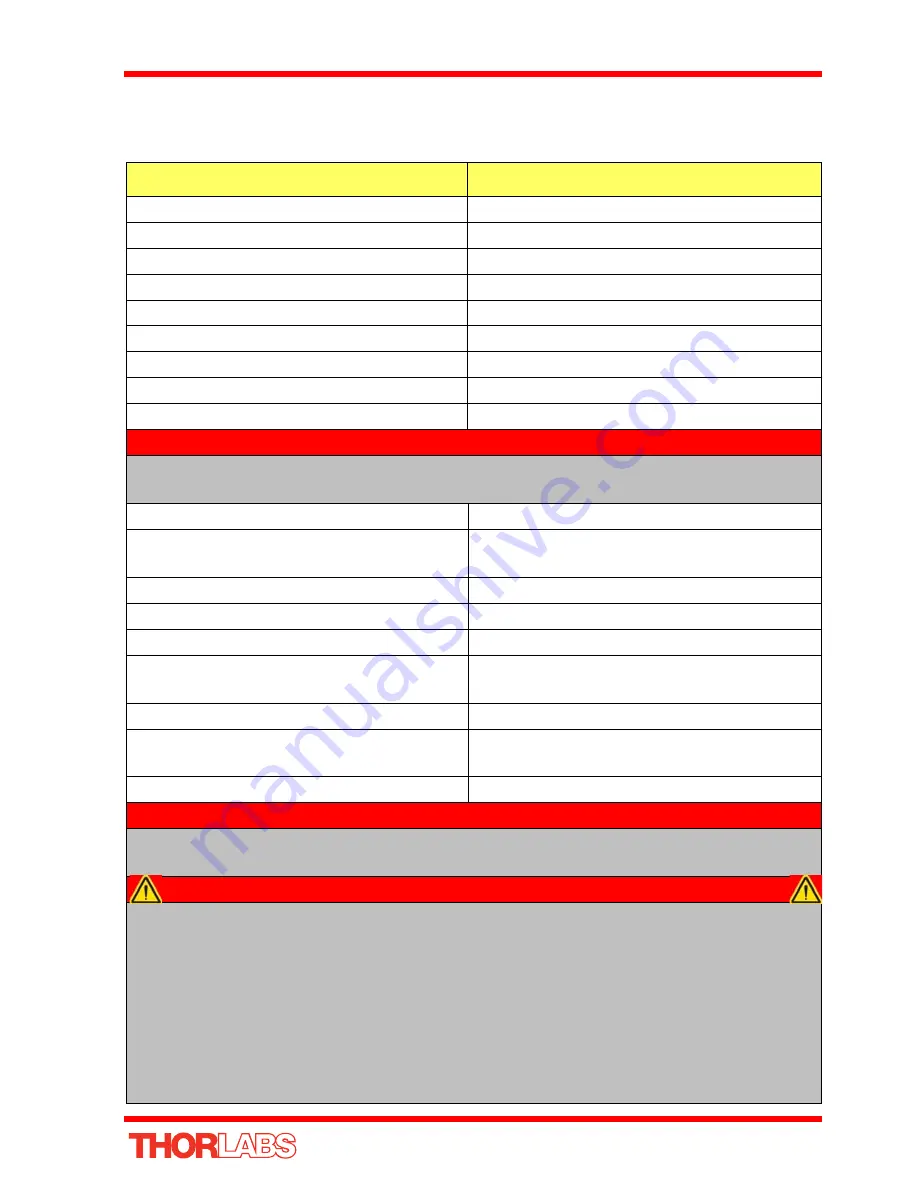

Specification

Parameter

Value

Travel

110 mm x 75 mm (4.3" x 2.95")

Max Speed

250 mm/s*

Acceleration

2000 mm/s*

Bidirectional Repeatability

0.25 µm

Unidirectional Repeatability

0.25 µm

Backlash

N/A (No Leadscrew)

Min Incremental Movement

0.1 µm

Home Location Accuracy

0.25 µm

Max Load

2.2 lbs (1 kg)

*Note

Depending on the application, heavy loads may affect the stage performance

and/or stability.

Absolute On-Axis Accuracy

<3 µm

Max Percentage Accuracy

X-Axis (110 mm) 0.0027%

Y-Axis (75 mm) 0.004%

Settling Time within 1 µm (600 g load)*

0.1 sec

Settling Time within 0.1 µm (600 g load) *

0.6 sec

Limit Switches

X and Y as Standard

Bearing Type

High Rigidity Recirculating Precision Linear

Bearing

Motor Type

Brushless DC Linear Motor

Dimensions (Mid Travel)

10.24 x 9.06" x 1.22"

(260.0 mm x 230.0 mm x 31.1 mm)

Weight (with cables)

7.0 lbs (3.2 kg)

*Note

The default tuning parameters can be changed to optimise settling times for a

specific load.

Caution

The maximum speed and acceleration values quoted can be safely achieved with

the maximum load and a high duty cycle. However in this case, some heating of

the stage may occur and dimensional stability of the stage may be affected. This

could result in less than optimal repeatability and accuracy. For cases were

repeatability and accuracy are critical it is recommended that the stage

temperature is allowed to reach a steady state before measurements are taken.

Alternatively the load, acceleration and duty cycle should be reduced from the

maximum values. Some trial and error in setting these values may be necessary

before the ideal settings are attained.