MEX VS

Chillers and inverter air / water heat pumps with axial fans

9

The MEX VS water chillers and heat pumps series are designed for applications in residential and commercial areas, These units

are extremely versatile and can operate in heat pump mode with the ability of producing hot water at a temperature of 58°C for

environmental heating and sanitary applications. The INVERTER compressor with brushless DC motor technology, matched with

electronic expansion valve, pump and variable speed blower are generally used for optimizing the power consumption and

efficient operation of the refrigerating components.

5.1

FRAME

All the unist of MEX VS series are made up of hot-galvanised thick sheet metal, painted with polyurethane powder enamels at

180°C to ensure the best resistance against atmospheric agents. The frame is self-supporting with removable panels. All screws

and rivets for outdoor installations are in galvanized steel.

5.2

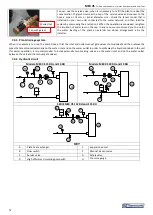

REFRIGERANT CIRCUIT

The refrigerant gas used in these units is R410A. The refrigerant circuit has been manufactured by means of international primary

brands components and according to the UNI EN 13134 Rule concerning welding procedures. The refrigerant circuit includes: 4

way reverse cycle valve, electronic expansion valve, liquid separator, liquid receiver, valves for maintenance and control, pressure

safety device, pressure transducers to accurately adjust the evaporating and condensing pressures, filters for throttling valve to

avoid its clogging.

5.3

COMPRESSORS

The installed DC inverter compressors are rotary hermetic twin rotary type designed to be used with R410 refrigerant.

The compressors are mounted in a separate chamber, isolated from the air stream in order to reduce the noise, and are equipped

with crankcase heater, In order to avoid the oil dilution which may cause seizure of the compressor. The crankcase heater

operates when the compressor remains off for at least 30 minutes and if the discharge temperature is below 20°C (with hysteresis

of 2.0°C). When the compressor restarts, the crankcase heater will stop operation. The crankcase heater works even if the unit is

in shut off mode, which will protect the compressor from restartup failure.

We recommend you to turn ON the unit and to put it in standby mode at least for 6 hours before starting the operation, especially

if the system has been completely turned off for a period of time.

The checking of the compressors is possible through removing the frontal and lateral panels of the unit allowing easy maintenance

of the compressors even when the unit is operation.

5.4

AIR SIDE EXCHANGERS

The air side exchangers are made up of copper pipes and aluminium fins. The tubes are mechanically expanded into the

aluminium fins to improve the heat exchange factor. The geometry of these condensers guarantee a low air side pressure drop

and, then, the use of low rotation (and low noise emission) fans.

5.5

FANS

The fans are axial type with aluminium aerofoil blades. They are statically and dynamically balanced and supplied complete of the

safety fan guard according to the CEI EN 60335-2-80 Rule (safety for electrical apparatus of domestic and similar use). They are

mounted on the unit frame by interposition of rubber vibration dampers. The electric motors are all brushless DC type with 8

poles (about 200/1000 rpm). The motors are directly driven with an integrated thermal overload protection. The protection class

of the motors is IP X44.

5.6

USER SIDE HEAT EXCHANGERS

The user side heat exchangers are made up of AISI 304 stainless steel braze-welded plates type. The user heat exchangers are

factory insulated with flexible close cell material and can be equipped with antifreeze heater (KA optional). Each heat exchanger is

provided with a temperature sensor working as antifreeze protection that activates the circulator, even in the case when the unit

is turned off when the conditions set in the controller have been occurred.

5.7

ELECTRIC BOX

The electric box is manufactured according to the current European Union laws. The accessibility to the board is possible after

removing the cover panel of the unit using proper tools. The protection degree is IP24. The terminal board is supplied with voltage

free contacts for remote ON-OFF, winter/summer change over, auxiliary heater, sanitary water temperature sensor control of

external 3-way valve and free contacts for remote control panel and for the management of the dual set point of operation.

5.8

CONTROL SYSTEM

All the units of MEX VS series are standard supplied with a microprocessor adopting an overheating control logic program through

the electronic expansion valve which is driven by the pressure transducers signals. The microprocessor is also capable of

controlling the following functions: water temperature regulation, antifreeze protection, compressors’ time setting, compressor

automatic starting sequence, alarm reset, alarm management and operating LED. Upon request, the microprocessor can be

connected to a BMS remote control system and to the simpler HNS system with our terminal units. The control system together

with the INVERTER technology and the on board sensors continuously monitor and adapt the performance of the inverter

compressor, of the pump and of the fan (2 fans for the models: 112 RH, 112T RH, 115 RH and 115T RH) according to the value of

cooling power at any working conditions requested by the user.

Содержание MEX VS 112 RH

Страница 39: ......