MEX VS

Chillers and inverter air / water heat pumps with axial fans

12

7

INSTALLATION

WARNING: All the operation described in next chapters MUST BE DONE BY TRAINED PEOPLE ONLY. Before any

operation on the unit, be sure that the electric supply is disconnected. Be sure also, using suitable obstructions,

that can avoid accidental power supply switching ON until the end of all operations.

7.1

GENERALITY

When installing or servicing the unit, it is necessary to strictly follow the rules listed in this manual, to conform to all the

specifications of the labels on the unit, and to take any possible precautions. Not observing the rules reported on this manual can

create dangerous situations.

After receiving the unit, immediately check its integrity. The unit left the factory in perfect condition; any eventual

damage has to be questioned to the carrier and recorded on the Delivery Note before signing it.

The company has to be informed, within 8 days, of the extent of the damage. The Customer should prepare a written statement of

any severe damage.

WARNING: The units are designed for outdoor installation. The place of installation must be entirely far away from

fire risk. All the necessary measures should be adopted in order to prevent the fire risk in the place of installation. The

outdoor ambient temperature shall not exceed 46°C. Above this value, the unit is no longer covered by the directives

in force in the area of pressure equipment.

WARNING: The unit should be installed so that adequate clearance is available for maintenance and repairation. The

warranty does not cover costs related to platforms or handling equipment necessary for any maintenance.

All maintenance and testing operations should be carried out only by QUALIFIED PERSONNEL.

Before any operation on the unit, make sure the power supply is disconnected.

WARNING: MOVING PARTS, RISK OF DEATH.

Disconnect the power supply and ensure that the fan is stopped before opening the front panel.

The temperatures of heads and discharge piping of the compressor are usually high.

Be careful when working near condensing coils.

The aluminum fins are very sharp and can cause serious injuries.

After the maintenance operations, close the panels tightly with the fastening screws.

7.2

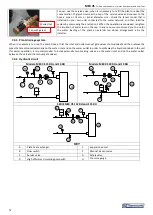

LIFTING AND HANDLING

When unloading and installing the unit, it is highly recommended to

avoid any sudden move in order to protect the inner components.

Units can be lifted by means of a forklift or, in alternative, of belts,

being sure not to damage the lateral panels and the cover. It is

important to keep the unit horizontal during these operations.

7.3

LOCATION AND MINIMUM TECHNICAL CLEARANCES

The all MEX VS units are designed for outdoor installation: any cover over the unit and location near trees (even if they partially

cover the unit) has to be avoided in order to prevent air recirculation. It is advisable to create a proper basement, with a size

similar to unit foot-print. Unit vibration level is very low: it is advisable however, to fit a rigid rubber band between basement and

unit base-frame. It is also possible to install anti-vibration supports (springs or rubbers) to keep vibrations at a very low level.

Absolute care has to be taken to ensure adequate air volume to the condenser. Re-circulation of discharge air has to be avoided;

failure to observe this point will result in poor performance or activation of safety controls. For these reasons it is absolutely

necessary to respect the following clearances:

MOD.

A

B

C

D

E

MEX VS 15 RH

1500

500

400

400

500

MEX VS 16 RH

1500

500

400

400

500

MEX VS 18 RH

1500

500

400

400

500

MEX VS 19 RH

1500

500

400

400

500

MEX VS 112RH/112T RH 1500

500

400

400

500

MEX VS 115RH/115T RH 1500

500

400

400

500

Содержание MEX VS 112 RH

Страница 39: ......