DRAG-GUN Plasma Cutter

10

Operating Manual 0-2682

F. Interlocks

F. Interlocks

F. Interlocks

F. Interlocks

F. Interlocks

If supply pressure falls below minimum requirements,

the lockout circuit will open, shutting off the DC Cir-

cuit. Similarly, the overtemp switch will open if the

unit becomes overheated, and will close again when

the unit cools to an acceptable temperature.

G. Parts-in-Place (PIP)

G. Parts-in-Place (PIP)

G. Parts-in-Place (PIP)

G. Parts-in-Place (PIP)

G. Parts-in-Place (PIP)

The torch head has replaceable contacts called Parts-

In-Place (PIP). These two contacts are made through

the brass washer inside the shield cup when it is in-

stalled. The torch will fail to operate if these contacts

are not made.

Torch Switch

PIP Pin

PIP Pin

Shield Cup

To Control

Cable Wiring

Butt Splice

A-00784

Figure 2-2 Parts-In-Place (PIP) Diagram

H. Duty Cycle

H. Duty Cycle

H. Duty Cycle

H. Duty Cycle

H. Duty Cycle

Duty cycle is the percentage of on-time (measured in

minutes) in a 10 minute period in which a system can

be operated, in an environment of a specified tem-

perature.

Exceeding duty cycle ratings will cause the thermal

overload protection circuit to become energized and

shut down output until the unit cools to normal oper-

ating temperature. Continual exceeding of duty cycle

ratings can cause damage to the cutting power source.

WARNING

When unit shuts down due to thermal overload,

power is still present throughout the entire sys-

tem.

2.2 General Product Description

2.2 General Product Description

2.2 General Product Description

2.2 General Product Description

2.2 General Product Description

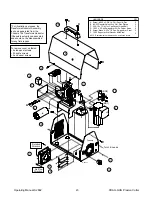

The DRAG-GUN Plasma Cutter is a small, easy-to-use

plasma cutting system which provides 12 amp maximum

output and a cut capacity of up to 1/8" (3.2 mm) of most

metals.

Everything you need to start cutting right away is in-

cluded with the DRAG-GUN - power supply with built-

in air compressor, pilot circuitry, all control circuitry, torch

and work lead (with torch consumable parts installed),

work cable and clamp, primary input cable, extra con-

sumable torch parts, and this instruction manual.

NOTE

The DRAG-GUN Cutter requires no assembly.

2.3 Technical Specifications

2.3 Technical Specifications

2.3 Technical Specifications

2.3 Technical Specifications

2.3 Technical Specifications

A. System Specifications

A. System Specifications

A. System Specifications

A. System Specifications

A. System Specifications

System

Specifications

Input Power

100 VAC 50Hz, 110 VAC 60Hz, Single Phase

100/110 VAC, 50/60Hz, Single Phase

120VAC ±10% , 50Hz, Single Phase

120VAC ±10% , 60Hz, Single Phase

220VAC ±10% ,50Hz, Single Phase

208/230VAC ±10% , 60Hz, Single Phase

Output Power

See subsection 2.3B

Duty Cycle

See subsection 2.3B

Maximum OCV

280 VDC

Pilot Circuitry

Capacitive Discharge (CD), Constant DC

Weight with Leads

55 lbs (24.9 kg)

Power Supply

L 16 in. (406 mm)

Dimensions

W 9 in. (229 mm)

H 10 in. (254 mm)

Work Cable

15 ft. (4.6 m)

Input Power Cable

6.6 ft. (2 m) minimum

PCH-10 70°

PCH-10 180°

L See subsection 2.4

W See subsection 2.4

Cutting Rating

12 Amps Max. Straight Polarity

Cut Capacity

Most metals up to 1/8 in. (3.2 mm) max.

Severance

Most metals up to 3/16 in. (4.8 mm)

Pierce Rating

1/16 in. (1.6 mm)

Transfer Distance

Approx. 1/8 in. (3.2 mm)

Gas Requirements

Compressed Air (Built-in)

Leads Length

20 ft. (6.1 m)

Torch Style

Torch Dimensions

Содержание Drag-gun

Страница 2: ......