Operating Manual 0-2682

9

DRAG-GUN Plasma Cutter

2.0 INTRODUCTION

2.0 INTRODUCTION

2.0 INTRODUCTION

2.0 INTRODUCTION

2.0 INTRODUCTION

This manual contains descriptions, operating instructions

and basic maintenance procedures for the DRAG-GUN

Plasma Cutter. Read this manual thoroughly. A com-

plete understanding of the characteristics and capabili-

ties of this equipment will assure the dependable opera-

tion for which it was designed.

WARNING

Service of this equipment is restricted to Thermal

Dynamics® trained personnel; unqualified person-

nel are strictly cautioned against attempting re-

pairs or adjustments not covered in this manual,

at the risk of personal injury and/or voiding the

Warranty.

2.1

2.1

2.1

2.1

2.1 What is Plasma?

What is Plasma?

What is Plasma?

What is Plasma?

What is Plasma?

A. Plasma Gas Flow

A. Plasma Gas Flow

A. Plasma Gas Flow

A. Plasma Gas Flow

A. Plasma Gas Flow

Plasma is defined as a gas which has been heated to

an extremely high temperature and ionized so that it

becomes electrically conductive. The plasma arc cut-

ting and gouging process use this plasma to transfer

an electrical arc to the workpiece. The metal to be cut

or removed is melted by the heat of the arc and then

blown away.

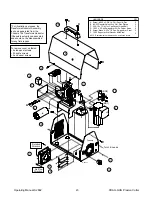

In a Plasma Cutting Torch a cool gas (in this case, air)

enters Zone B (refer to Figure 2-1), where a pilot arc

between the electrode and the torch tip heats and ion-

izes the gas. The main cutting arc then transfers to

the workpiece through the column of plasma gas in

Zone C.

By forcing the plasma gas and electric arc through a

small orifice, the torch delivers a high concentration

of heat to a small area. The stiff, constricted plasma

arc is shown in Zone C (Figure 2-1). Direct current

(DC) straight polarity is used for plasma cutting, as

shown in the illustration.

Zone A (Figure 2-1) is used as a secondary gas that

cools the torch. This gas assists the high velocity

plasma gas in blowing the molten metal out of the cut

allowing for a fast, slag-free cut.

;;

;;

;;

;

;

;

;

;

;;

;;

A-00002

Workpiece

Power

Supply

+

_

C

B

A

Figure 2-1 Typical Torch Head Detail

B. Gas Distribution

B. Gas Distribution

B. Gas Distribution

B. Gas Distribution

B. Gas Distribution

The single gas used is internally split into plasma and

secondary gases. The plasma gas flows into the torch

through the negative lead, through the gas distribu-

tor, around the electrode, and out through the tip ori-

fice. The secondary gas flows down around the out-

side of the torch gas distributor, and out between the

tip and shield cup around the plasma arc.

C. Pilot Arc

C. Pilot Arc

C. Pilot Arc

C. Pilot Arc

C. Pilot Arc

When the torch is started a pilot arc is established be-

tween the electrode and cutting tip. This pilot arc cre-

ates a path for the main arc to transfer to the work.

D. Capacitive Discharge (CD)

D. Capacitive Discharge (CD)

D. Capacitive Discharge (CD)

D. Capacitive Discharge (CD)

D. Capacitive Discharge (CD)

Because direct current (DC) alone is not sufficient to

strike and maintain the pilot arc, CD is also used. The

capacitive discharge jumps between the tip and elec-

trode with the DC following. (Note: This may not ap-

ply to all unit models).

E. Main Cutting Arc

E. Main Cutting Arc

E. Main Cutting Arc

E. Main Cutting Arc

E. Main Cutting Arc

DC power is also used for the main cutting arc. The

negative output is connected to the torch electrode

through the torch lead. The positive output is con-

nected to the workpiece via the work cable and to the

torch through a pilot wire.

Содержание Drag-gun

Страница 2: ......