UNPACKING AND SET-UP

1. Open carton, then remove ramp and shipping boards.

2. Connect foot-operated air valve to 110 psi maximum air supply. The lift may be damaged and/or

personal injury may result if the pressure exceeds the maximum 110 psi rating.

3. Stand clear of lift table, and depress the UP side of foot valve to raise table.

4. To lower table, lift detent bar from safety latch and lower to next position or to floor.

5. Mount ramp to top by inserting ramp tabs into slots in lift top.

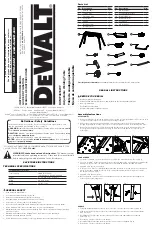

UNPACKING AND SET-UP OF EXTENSION COMPONENTS

1. Open cartons containing side and end extension components. Refer to the illustration and parts list page.

2. Connect Air Lift to 100 psi air then raise lift and engage safety detent bar.

3. Insert the 53-

1/4” stabilizer shafts thru each frame end. Place axle extensions with the wheels secured

by two spiral retaining rings onto shaft then retain with quick pins. Place stabilizer feet onto shaft at outside

frame and retain with quick pins.

4. Insert the two 3/4” pipes thru holes near center of lift top. Place side extensions onto these pipes

and retain with quick pins at each end of the pipe.

5. Pull side extensions out against quick pins and center side extensions on the Air Lift.

6. Place end extension onto lift top and side extensions aligning pipe holes , then insert 1” pipe. Install quick

pins at pipe ends. Secure end extensions to both lift top and side extensions to both lift top and side

extension using ten 5/16-18 cap screws and nuts for each end extension. Note: eight bolts go down

and one is located at each side near bend.

7. Attach detent handle extensions on each side of detent safety bar. See detail on illustration and parts list

page.

8. To mount ramps, insert ramp tabs into slots in the end extension, opposite the end with the wheel

OPERATION

1. Loads must be centered on table at all times. Table is rated for a maximum load of 1800 lbs.

2. Loads must be firmly positioned and secured on table at all times. Tie-down straps must be used

in conjunction with the holes provided in the lift top.

3. All moving parts have been lubricated at the factory and should be re-lubricated every (6) months

to prevent galling. Grease zerks are located at each end of frame pivot shaft and at top ends of

inside frame assembly.

4. Lightly oil cylinder rod when it becomes dry.

5. Squirt some oil through bleed hole in plate end of cylinder to lubricate piston and its seal every

(6) months.

6. Pivot shaft set screws should be checked frequently to be sure they are tight. These are

located at the top end of the inside frame assembly.

NOTE: READ ENTIRE MANUAL TO COMPLY WITH ALL SAFETY AND SERVICE PRECAUTIONS.

DEATH, PERSONAL INJURY AND/OR PROPERTY DAMAGE MAY OCCUR UNLESS INSTRUCTIONS

ARE FOLLOWED CAREFULLY.

Содержание 16867G

Страница 3: ...MOUNTING ILLUSTRATION AND PARTS DRAWING ...