4

Electrical

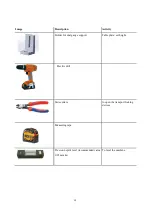

Oscillating Tool

High-frequency electric-

driven tool

with

80W and 250W power

options. Max cutting speed

1m/s for soft and medium-

density materials.

Chevron

board,

Corrugated board, Gasket,

KT board, Gray cardboard,

PE, XPE, EPE, PU leather,

PU composite sponge, Coil

car mat, etc.

Pneumatic

Oscillating Tool

Powerful air-driven tool

with extended stroke for

dense materials up to

50mm thick.

Composites, Honeycomb

board, Asbestos gasket,

Graphite gasket, Sponge,

EPE, etc.

Kiss-Cut Tool

Half-cut tool

for

vinyl materials.

Vinyl, sticker, reflective

film, etc.

Driven Rotary Tool

Cutting tool with driven

rotary blade for fabrics and

technical textiles with high

processing speed.

Fabrics, carbon fiber, glass

fiber, aramid, carpet, etc.

V-Cut Tool

Tool with 5 cutting

angles.

Create

3D

structural design.

Honeycomb

board,

sandwich

board,

KT

board, Gray board, etc.

Содержание XYZ 2517

Страница 1: ...TEXI XYZ 2517...

Страница 4: ......

Страница 17: ...13 Without Length Length 2 4m Width Width 2 4m...

Страница 19: ...15 M16 x 70mm...

Страница 20: ...16 3 3 Base machine installation Picture 1...

Страница 21: ...17 Picture 2...

Страница 22: ...18 Picture 3 Picture 4...

Страница 26: ...22 3 5 Assemble the Milling support device The total height 2 8 m...

Страница 27: ...23 3 5 1 Connect cables in the milling device support...

Страница 31: ...27...