17

Carefully handle both the tool and individual grinding wheels to avoid chipping or

cracking. Install a new wheel if tool is dropped while grinding. Do not use a wheel

that may be damaged. Fragments from a wheel that bursts during operation will fly away

at great velocity possibly striking you or bystanders.

Use clamps to support workpiece whenever practical. Never hold a small workpiece

in one hand and the tool in the other hand while in use. Allow for sufficient space,

at least 6", between your hand and the spinning bit. Round material such as dowel rods,

pipes or tubing have a tendency to roll while being cut, and may cause the bit to “bite” or

jump toward you. Clamping a small workpiece allows you to use both hands to control the tool.

Inspect your workpiece before cutting. When cutting irregularly shaped workpieces,

plan your work so it will not slip and pinch the bit and be torn from your hand. For

example, if carving wood, make sure there are no nails or foreign objects in the workpiece.

Nails or foreign objects can cause the bit to jump.

Never start the tool when the bit is engaged in the material.

Avoid bouncing and snagging the wheel, especially when working corners, sharp

edges etc. This can cause loss of control and kick-back.

The direction of feed with the bit into the material when carving, routing or cutting

is very important. Always feed the bit into the material in the same direction as the

cutting edge is exiting from the material (which is the same direction as the chips

are thrown). Feeding the tool in the wrong direction, causes the cutting edge of the bit to

climb out of the work and pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed or bogged down, turn the tool “OFF” by

the switch. Wait for all moving parts to stop and unplug the tool, then work to free

the jammed material. If the switch to the tool is left “ON” the tool could restart unexpectedly

causing serious personal injury.

Do not grind or sand near flammable materials. Sparks from the wheel could ignite these

materials.

Do not touch the bit or collet after use. After use the bit and collet are too hot to be

touched by bare hands.

Check any parts concerned. Clean such parts or replace them, if required.

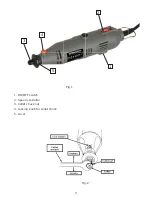

Содержание TTRTK

Страница 3: ...2 Exploded Assembly Diagram NOTICE Actual product may vary from pictures shown...

Страница 6: ...5 Picture No 1 3 2 1 Picture No 2 4 6 5...

Страница 7: ...6 Picture No 4 Picture No 3 7 9 8 11 10...

Страница 8: ...7 Picture No 6 Picture No 5 12 13...

Страница 9: ...8 Picture No 8 Picture No 7 14 15 16 19 18 17 20...

Страница 10: ...9 Picture No 10 Picture No 9 21 22 23 26 25 24...