16

Keep hands away from cutting area.

Do not use dull or damaged cutters.

Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over rated speed can fly apart and cause injury.

Do not operate the flexible shaft with a sharp bend. Over bending the shaft can

generate excessive heat on the jacket or hand piece. The recommended minimum is 5" radius.

Never work in area which is soaked with a liquid, such as a solvent or water, or

dampened such as newly applied wallpaper. There is an electrical shock hazard when

working in such conditions with a power tool and heating of the liquid caused by scraping action

may cause harmful vapors to be emitted from work piece.

Always wear eye protection and a dust mask for dusty applications and when sanding.

Sanding particles can be absorbed by your eyes and inhaled easily and may cause health

complications.

Use special precautions when sanding chemically pressure treated lumber, paint that

may be lead based, or any other materials that may contain carcinogens.

A suitable breathing respirator and protective clothing must be worn by all persons entering the

work area. Work area should be sealed by plastic sheeting and persons not protected should be

kept out until work area is thoroughly cleaned.

Always wait until the machine has come to a complete stop before placing it down.

Before any work on the machine (e. g., maintenance, tool change, etc.) as well as

during transport and storage make sure the switch is off. Unintentional actuation of the

On/Off switch can lead to injuries.

After changing the bits or making any adjustments, make sure the collet nut and

nose cap are both securely tightened. Loose adjustment devices can unexpectedly shift,

causing loss of control, loose rotating components will be violently thrown.

Do not reach in the area of the spinning bit. The proximity of the spinning bit to your

hand may not always be obvious.

Allow brushes to run at opera ting speed for at least one minute before using wheel.

During this time no one is to stand in front or in line with the brush. Loose bristles or

wires will be discharged during the run-in time.

Wire and bristle brushes must never be operated at speeds greater than 15,000/min.

Direct the discharge of the spinning wire brush away from you. Small particles and tiny

wire fragments may be discharged at high velocity during the “cleaning” action with these

brushes and may become imbedded in your skin. Bristles or wires will be discharged from the

brush at high speeds.

Содержание TTRTK

Страница 3: ...2 Exploded Assembly Diagram NOTICE Actual product may vary from pictures shown...

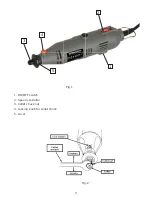

Страница 6: ...5 Picture No 1 3 2 1 Picture No 2 4 6 5...

Страница 7: ...6 Picture No 4 Picture No 3 7 9 8 11 10...

Страница 8: ...7 Picture No 6 Picture No 5 12 13...

Страница 9: ...8 Picture No 8 Picture No 7 14 15 16 19 18 17 20...

Страница 10: ...9 Picture No 10 Picture No 9 21 22 23 26 25 24...