Document 57.4400.7200 - 1

st

Edition 03/2005

INDEX

iii

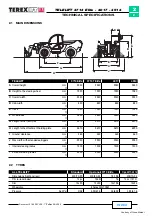

TELELIFT 3713 Elite - 4017 - 4514

INTRODUCTION

The hydraulic energy produced by the drive pump

(pos.

2)

is converted into mechanical power by a closed-loop

hydrostatic motor, model Bosch-Rexroth A6VM80

(pos.

5)

equipped with adjustment valve of DA1 type and with

flush valve for reducing the max temperatures inside

the drive circuit.

The motor is flanged to a two-speed mechanical

gearbox, model 357

(pos. 6)

manufactured by Dana.

Speeds are engaged by a special oil-dynamic cylinder

located inside the gearbox, while the selection of the

first and second speed is controlled by a 4-way/3-

position solenoid valve

(pos. 7)

of the on/off type.

The mechanical torque at the gearbox output is

transmitted to the front axle

(pos. 26)

and the rear axle

(pos. 25)

, both model 212 manufactured by Dana,

through Cardan shafts.

The hydraulic drive

(pos. 12)

of “load sensing” type with

a displacement of 315 cm

3

, receives oil from the priority

line of the pump

(pos. 3)

in relation to the “load sensing”

signal sent by the hydraulic drive and connected to such

pump with function of pilot signal. In this way, the input

flow to the hydraulic drive will be exactly the one needed

for the instantaneous steering functions; any excess flow

of the pump will be available for the functions of the

telescopic boom.

The steering circuit is protected against input

overpressures by a pressure reducing valve set at 140

bar. On the two delivery lines, there are other two

reducing valves with anti-shock function set at 200 bar.

The scope of these two valves is limiting possible shocks

on the steering wheel due to overstress on the steering

cylinders. The three pressure reducing valves are

installed in the hydraulic drive

(pos. 12)

and cannot be

regulated from the outside.

The steering circuit is completed by the front steering

cylinder

(pos. 14)

, the rear steering cylinder

(pos.

15)

[these cylinders being integral part of the front axle

(pos. 26)

and the rear axle

(pos. 25)

respectively] and

by a 4-way/3-position solenoid valve

(pos. 13)

for the

selection of the three different steer modes (rear wheels

straight, co-ordinate front/rear steering and independent

front/rear steering). When the solenoid valve

(pos. 13)

is not energised, the front steering cylinder is fed by the

hydraulic drive and the rear cylinder is blocked. When

one magnet or the other of the solenoid valve

(pos. 13)

is energised, the chambers of the cylinders are

connected in a different manner thus causing the desired

effect on the steering mode.

The Bucher/Tecnord electro-proportional distributor

(pos. 16)

, with 4 modular sections, receives oil from

the secondary line of the pump

(pos. 3)

and feeds all of

the movements of the telescopic boom.

Содержание TELELIFT 3713 Elite

Страница 4: ...Courtesy of Crane Market...