9

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in equipment

damage or equipment damage.

Capacitors can store electrical energy when power is off.

Electrical shock can result if you touch the capacitor terminals

and discharge the stored energy. Exercise extreme caution

when working near capacitors. With power off, discharge

stored energy by shorting across the capacitor terminals with a

15,000

−

ohm, 2

−

watt resistor.

Always check capacitors with power off. Attempting to

troubleshoot a capacitor with power on can be dangerous.

Defective capacitors may explode when power is applied.

Insulating fluid inside is combustible and may ignite, causing

burns.

!

WARNING

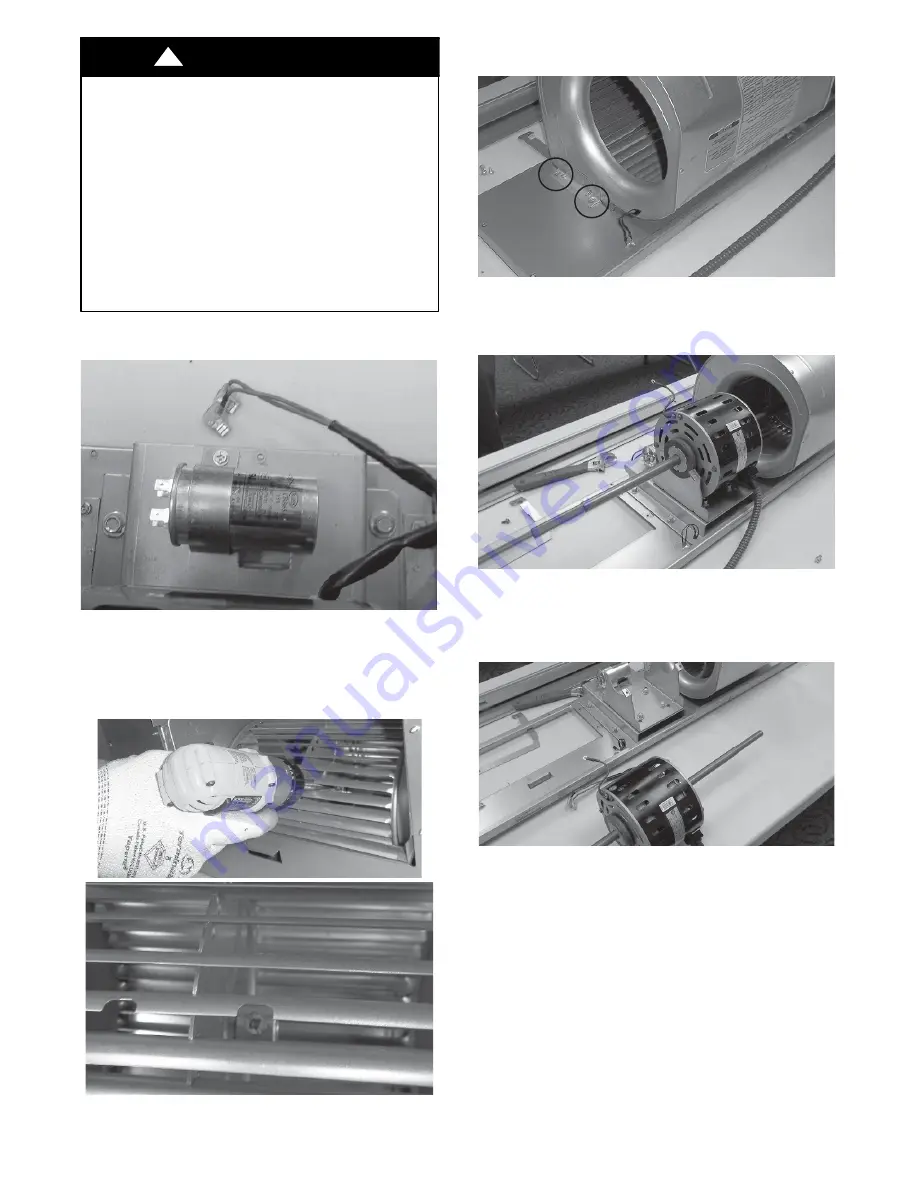

4. Disconnect capacitor leads from capacitor.

A13393

Fig. 15

−

Capacitor Leads

5. Loosen blower

−

wheel set screws from each motor shaft, ac-

cessing them through the blades of the blower wheels, with

a Phillips screwdriver.

A13394

Fig. 16

−

Loosen Blower Set Screw

6. Disconnect one of the blower housings by removing the

four housing screws.

A13395

Fig. 17

−

Disconnect Blower Housing

7. Remove housing from support plate and motor shaft.

A13396

Fig. 18

−

Remove Blower Housing

8. Pull motor out of second housing, which can remain at-

tached to the support plate.

A13397

Fig. 19

−

Remove Motor from Second Housing

9. Reverse these steps to reinstall.

F. FMC4Z & FMU4Z

−

Disconnecting the Blower Assembly

1. Disconnect power.

2. Remove control box cover (four screws). (See Fig. 20)