the waveforms displayed on the oscilloscope resemble those

in

.

-

switch off the ohmic load and switch off the main switch.

If one of the two signals is absent the control board should be

replaced (

Otherwise, if the machine does not supply AC

current the SCR module should be replaced, or if the worst comes

to the worst replace the secondary board.

Set switch SW2 to TIG/2T (toward to the top) and switch SW2 to

LIFT (in the centre). Connect the TIG torch and press the button to

verify that relay K1 closes

; if not check whether:

After checking operation for point 1.3 A), press the button and

check whether:

- the solenoid valve closes (fig. 2A); if not check whether:

- the voltage over the female fastons (

) is equal to 230Vac

±10%. If voltage is present this means the solenoid valve is

faulty, otherwise check the operation of relay K2 on the

secondary board;.

-

- the voltage over pin 1 (+) and pin 25 of J9 (control board) is

equal to +15Vdc ±20%, otherwise replace the control board.

Set switch SW2 to TIG/2T (as high as it will go) and switch SW3 to

AC (as low as it will go). Now reconnect only fastons J1 and J3 to

the HF generator board (

) and faston J1 on the support

board.

The high frequency voltage will permanently damage

any instrument connected to the generator.

With the TIG torch still connected and pressing the button check

whether:

-

the HF generator board starts to hum for about 2 seconds

(high frequency in torch); otherwise make sure the voltage

over female fastons J1 and J3 (

), disconnected from the

HF board, is equal to 230Vac ±10%; if voltage is present the

HF board is faulty; if not check the operation of transformer T1

and SCR Q1;

On the front panel set switch SW2 to MMA (as low as it will go),

switch SW3 to DC-LIFT (in the centre) and the welding current to

maximum. Under the load conditions shown in

, switch on the

machine and leave it in operation until the thermostatic capsules

trigger (machine in alarm). After making sure the internal wiring is

positioned correctly re-assemble the machine once and for all.

with the machine set up according to the instructions in the

handbook make a test weld with an electrode diam. 2.5 and the

current setting at 80A. Monitor the dynamic behaviour of the

power source, also checking for the presence of the Arc Force, by

first operating key SW1 and then the encoder.

with the machine set up according to the instructions in

the handbook make a test weld with a grey electrode diam. 2.4

and an argon gas bottle (gas flow at 4.5 litres/minute). Make a

weld on iron or steel with a current setting of 80A, monitor the start

and arc stability and make sure the piece melts properly. Also

check all the main properties of the machine that can be set from

the digital panel (see TAB.1).

with the machine set up according to the instructions in

the handbook make a test weld with a green electrode, diam.

1.6mm, and the argon gas bottle (gas flow at 10 litres/minute).

Make a weld on aluminium with a current setting of 40A and

Duty Cycle 80%, monitor the start and arc stability and make

sure the piece melts properly. Also check all the main properties

of the machine that can be set from the digital panel (see

TAB.1).

Fig. J

N.B.

fig. 3).

A) Checking torch button operation

(fig. 4)

B) Checking solenoid valve operation

fig.4

on the secondary board relay K2 closes (fig. 6); if not check

whether:

C)Checking HF generator operation

fig. 4

WARNING!

fig.4

D) Running time test and closing the machine

fig. I

E) Welding test

MMA:

TIG/DC:

TIG/AC:

1.3 Operational tests

- Operation of the torch button;

- Operation of diode bridge D2 on the torch button board;

- Operation of transformer T1 on the torch button board;

- 20-

TECHNOLOGY TIG 172 AC/DC

FIGURA E

6

3

2

1

4 5

1 1 0 0 0 0

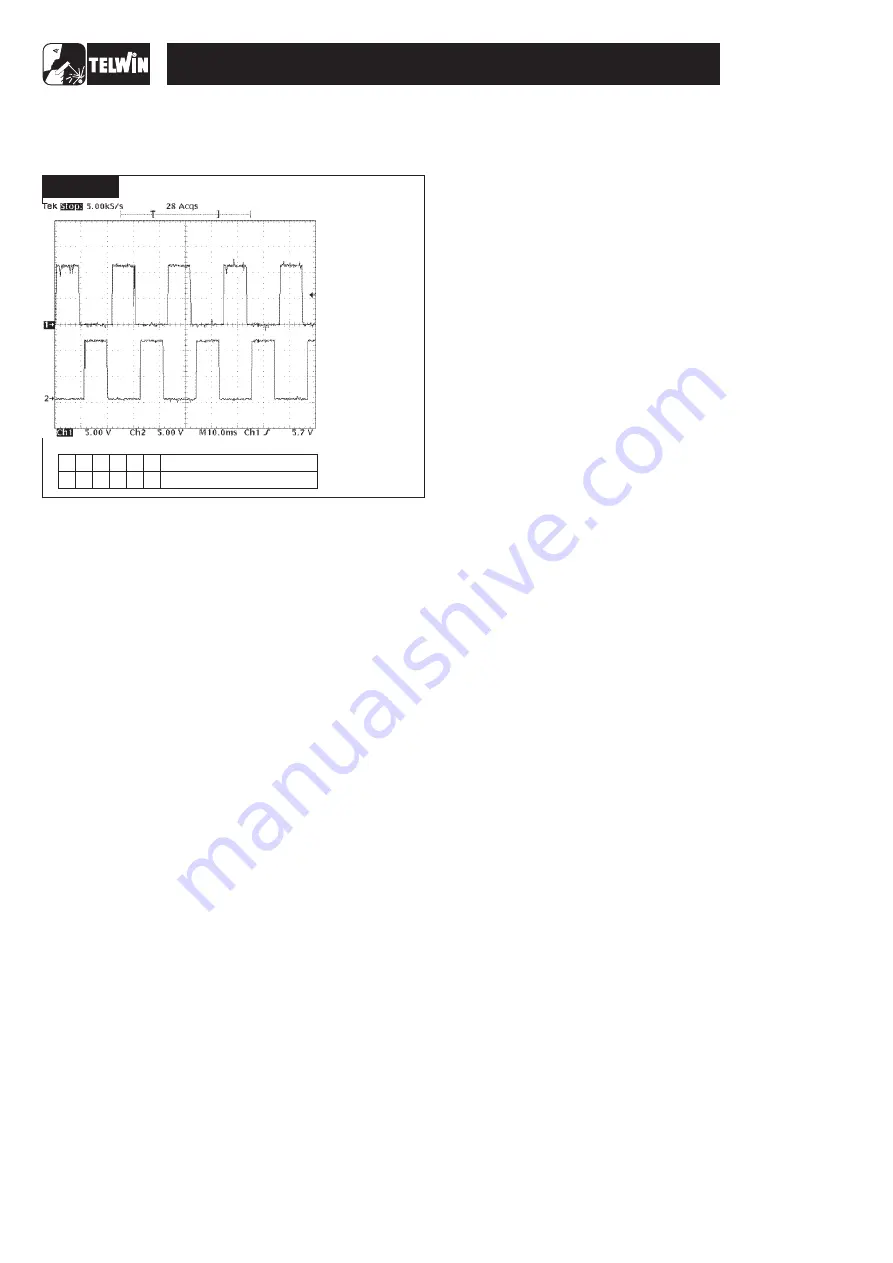

FIGURE J

SETTINGS

· THE FREQUENCY ON

CH1 AND CH2 IS

45KHz ±10%;

· AMPLITUDE ON CH1

AND CH2 IS 12V ±10%;

:

· PROBE CH1 x10;

· 5 V/Div;

· PROBE CH2 =10;

· 5V/Div;

· 10 sec/Div.

µ

VERIFY THAT

Number switch

Position switch

Содержание TECHNOLOGY TIG 172

Страница 7: ... 7 TECHNOLOGY TIG 172 AC DC WIRING DIAGRAMS General wiring diagram ...

Страница 8: ... 8 TECHNOLOGY TIG 172 AC DC Wiring diagram primary board Power Wiring diagram primary board Driver ...

Страница 10: ... 10 TECHNOLOGY TIG 172 AC DC Wiring diagram control board Digital Wiring diagram control board Analogyc ...

Страница 11: ... 11 TECHNOLOGY TIG 172 AC DC Wiring diagram control board In Out Wiring diagram secondary board Power ...