J) Repeat this test on Q1, Q2, Q3 as well.

if the signal is not

present there could be a fault in the IGBT driver circuit,

specifically ISO1 and ISO2 (

), or in the control board (

, in which case we recommend replacing the board).

K) Switch off the HV and replace the 2 fastons connecting the

primary board and the power transformer (CN3 and CN10).

L) Switch on the HV and the variac (initially set to 0V), close the

main power supply switch on the machine and gradually

increase the voltage generated by the variac until it reaches

26Vac.

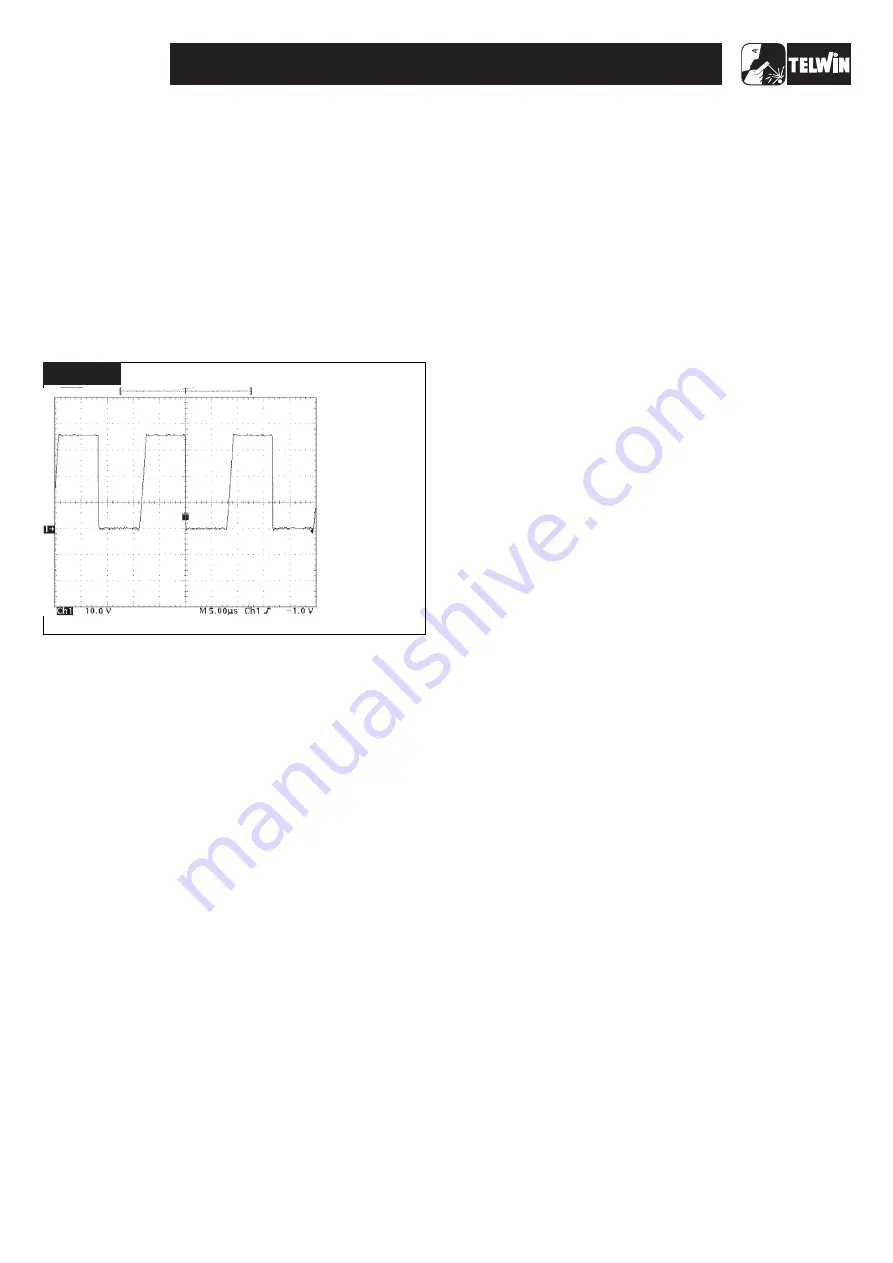

M) Set up the oscilloscope with the voltage probe x100

connected between the collector (probe) and the emitter

(earth) of IGBT Q4 on the primary board (

).

N) Make sure the waveform shown on the oscilloscope

resembles

O) Repeat this test on Q2 as well, using the differential probe.

If the signal is not present there may be a fault in the IGBT's

(

).

P) Return the variac voltage to 0V, switch off the machine and the

HV power supply.

Q) Disconnect the HV power supply, replace jumper JP1 on the

board.

R) Switch the machine on again and gradually increase the

voltage generated by the variac to 150Vac 5% then make sure

an alarm is registered with yellow LED D8 on and alarm “AL.1”

shown on the display.

S) Increase the voltage on the variac to 230Vac and make sure

the alarm ceases (yellow LED D8 goes off).

T) Increase the voltage on the variac yet again to 300Vac 5% and

make sure the machine registers an alarm again. Return the

variac voltage immediately to 230Vac and switch off the

machine.

if an alarm persists (and is not caused by a fault in the control

board) there could be a fault in opto-isolator ISO3 or integrated

circuit U3 on the primary board (

).

N.B.

fig. 5

fig.

3

fig. 5

fig. E.

N.B.

fig.5

N.B.

fig. 3

7.0 Repairs, replacing the boards

If repairing the board is complicated or impossible, it should be

completely replaced.

The board is identified by a 6-digit code (printed in white on the

component side after the initials TW). This is the reference code

for requesting a replacement: Telwin may supply boards that are

compatible but with different codes.

before inserting a new board check it carefully for

damage that may have occurred in transit. When we supply a

board it has already been tested and so if the fault is still present

after it has been replaced correctly, check the other machine

components. Unless specifically required by the procedure, never

alter the board trimmers.

If the fault is in the control board remove it from the primary board

as follows:

-

with the machine disconnected from the main power supply

disconnect all the wiring from the control board;

-

cut any bands restricting the board;

-

remove the control board from the spacers attached to the

primary board;

for assembly proceed in the reverse order.

If the fault is in the control board we strongly advise replacing it

without further intervention.

If the fault is in the primary board remove it from the machine

structure as follows:

-

with the machine disconnected from the main power supply

and after removing the control board, disconnect all the wiring

from the primary board;

-

cut any bands restricting the board (e.g. on the power supply

cable and primary connections);

-

undo the screws fastening the front and back panels and

remove the panels from the machine structure;

-

undo the screws fastening the primary board to the machine

structure;

-

remove the primary board by lifting it upwards.

for assembly proceed in the reverse order.

The 4 IGBT's are attached to 2 different dissipators and whenever

a replacement is required, both IGBT's should be replaced.

Before making the replacement make sure the components

piloting the IGBT's are not also damaged:

-

with the multimeter set in

mode make sure there is no

short circuit on the PCB between the 1 and 3 bump contacts

(between gate and emitter) corresponding to each

component;

-

alternatively, resistors R3, R4, R7, R8 could have burst and/or

diodes D11, D12, D15, D16 may be unable to function at the

correct Zener voltage (this should have shown up in the

preliminary tests);

-

clean any irregularity or dirt from the dissipators. If the IGBT's

have burst the dissipators may have been irreversibly

damaged: in this case they should be replaced;

-

apply thermo-conductive grease following the general

WARNING!

N.B.

N.B.

Please read the procedure for replacing the IGBT's

carefully: (fig. 5).

ohm

7.1 Removing the control board (fig. 3)

7.2 Removing the primary board (fig. 3)

-

Unscrew the four (4) nuts that fix the dissipator onto the

card;

-

unscrew the four (4) screws that fix the four (4) IGBT onto

the dissipator;

-

unscrew the two (2) screws that fix the two diode bridges

onto the dissipator;

-

remove the four (4) IGBT and the two (2) diode bridges by

unwelding the reophores, then remove tin from the

printed plates;

-

remove dissipator from card.

st

rd

- 17 -

TECHNOLOGY TIG 172 AC/DC

SETTINGS:

· PROBE x10;

· 10V/Div;

· 5 sec/Div.

±

.

· AMPLITUDE IS:

35V ±20%.

µ

TIME TOLLERANCE 20%.

VERIFY THAT

FIGURE E

Содержание TECHNOLOGY TIG 172

Страница 7: ... 7 TECHNOLOGY TIG 172 AC DC WIRING DIAGRAMS General wiring diagram ...

Страница 8: ... 8 TECHNOLOGY TIG 172 AC DC Wiring diagram primary board Power Wiring diagram primary board Driver ...

Страница 10: ... 10 TECHNOLOGY TIG 172 AC DC Wiring diagram control board Digital Wiring diagram control board Analogyc ...

Страница 11: ... 11 TECHNOLOGY TIG 172 AC DC Wiring diagram control board In Out Wiring diagram secondary board Power ...