B) Removing the secondary board (fig. 5)

C) Replacing the control board (fig. 2A)

1.1 Preparation for testing

1.2 Scheduled tests

Unless the dissipator has been damaged by a destructive

explosion of the diodes, the secondary board should not generally

be removed and the diodes can be replaced directly with the board

mounted on the machine. In any case, it should be specified that to

remove it is necessary to

:

-

remove the base by undoing the 4 screws;

-

turn the machine upside down and undo the 6 screws

fastening the base assembly to the metal structure;

-

disconnect all wiring that hampers removal of the base

assembly;

-

after separating the base assembly disconnect the fastons

from the thermostatic capsule and make the replacement.

For assembly proceed in the reverse order.

-

operating on the upturned machine, undo the screws fastening

the damaged components to the dissipator and unsolder the

metal tab;

-

after removing the components clean the dissipator, removing

dirt and irregularities;

-

apply thermoconductive grease following the general

instructions;

-

place the components on the dissipator to correspond with the

soldering zones and fasten them down with the screws (torque

wrench setting 1.4 Nm 20%);

-

solder the rheofores taking care not to let the tin form short

circuits.

make sure that R1 and C1 (secondary snubber) are correctly

soldered to the PCB.

If the fault is in the control board we strongly advise replacing it

without further intervention.

-

undo the 4 screws on the front panel;

-

disconnect all the connectors.

For assembly proceed in the reverse order.

Testing should be carried out on the assembled machine before

closing the top cover. During tests never ever commute the

selectors or operate the ohmic load contactor with the machine in

operation.

A) Using cables with suitable dinse connectors, connect the

machine to the ohmic load (two ohmic loads connected in parallel

should be available).

To connect the negative of the ohmic loads to the torch

connector it is necessary to use the adapter with torch button

simulator. If no adapter is available, it can always be ordered from

Telwin.

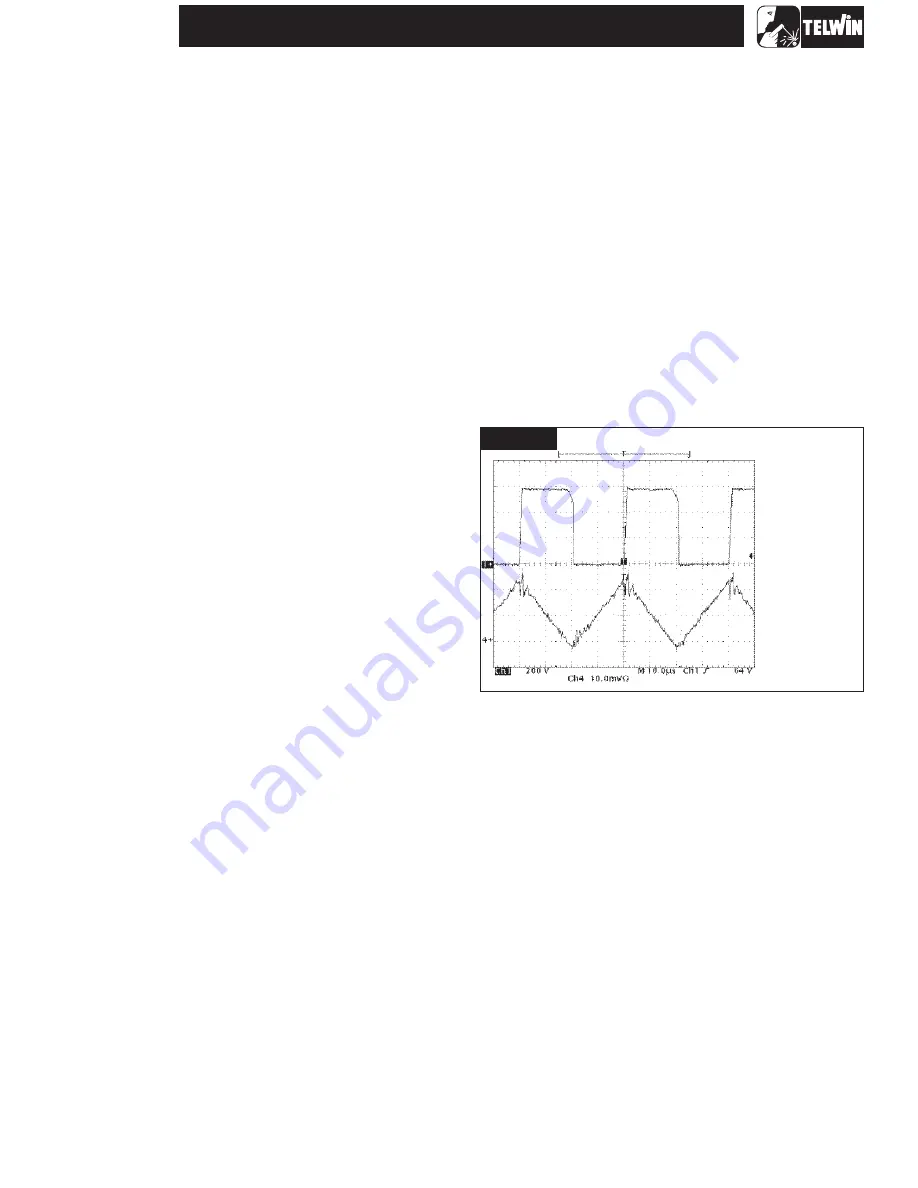

B) Connect a voltage probe x100 between the collector (probe)

and emitter (earth) of IGBT 6.

C) Pass the current probe of the Hall effect transducer along the

cable connecting the power transformer at eyelet C BASSO with

the reference arrow pointing into C BASSO.

D) Lastly, connect the Hall Probe and the current probe to the

oscilloscope.

E) Keep the auxiliary cables (

and

) connected to the

machine as previously.

F) On the control board position the current potentiometer to

minimum.

G) Connect the power supply cable of the machine to a 3-phase

variac with variable output 0-500 Vac.

To obtain the waveform it is necessary to press the torch

button simulator several times, because the machine remains

switched on for a maximum of about 2 seconds.

-

with the loads switched off, set the machine in “

”, by

first pressing the air button on the front panel and then closing

switch SW1 (ON) of the wiring in fig. A. Keep the air button

pressed for more than 6 sec, after which diode D3 will start to

flash (this status will remain until the machine is switched off).

In this mode we disable HF (which is lethal to any

instrument connected to the machine) and air input. Before

continuing testing make sure the machine is in test mode.

-

switch on the machine and the variac and take the latter to 400

Vac.

-

press the torch button simulator and make sure the voltage

and current waveforms displayed on the oscilloscope

resemble those in

-

switch off the auxiliary power supply, the machine and the

variac;

-

disconnect the wiring shown in fig. A from the machine and

restore the original wiring on the auxiliary transformer and on

the power supply board;

-

disconnect the wiring shown in fig. B from the machine and

restore the original wiring between the control board and the

primary board;

-

connect the machine to the 3-phase 400Vac power line.

-

switch on the machine and set it to “

”, by first

pressing the air button on the front panel and then closing the

main switch (ON). Keep the air button pressed for more than 6

sec, after which diode D3 will start to flash (this status will

remain until the machine is switched off).

In this mode we disable HF (which is lethal to any

instrument connected to the machine) and air input.

Before continuing with testing make sure the machine is in test

mode.

set up the ohmic loads with the switch settings as in the table in

-

on the front panel position the current potentiometer to

minimum;

-

start up the ohmic load, press the torch button simulator and

verify that:

-

the waveforms displayed on the oscilloscope resemble

those in

;

-

the output current is equal to +20Adc 10% and the output

voltage is equal to +88Vdc 10%;

(fig. 4)

N.B.

B) Take special note of the procedure for replacing the

secondary diodes:

N.B.

N.B.

N.B.

fig. A

fig. B

N.B.

A) Loadless test:

test mode

N.B.

fig. F.

B) Minimum load test:

test mode

N.B.

fig. G;

fig. G

±

Before proceeding with testing, we should

remind you that during these tests the power source is powered

and therefore the operator is exposed to the danger of electric

shock. The tests described below can be used to check the power

source under load.

±

±

TESTINGTHE MACHINE

WARNING!

-

17

SUPERIOR PLASMA 90 HF

FIGURE F

SETTINGS

PROBE CH1 x10;

5V/Div;

PROBE CH4 = 5A/Divv;

10mV/Div;

10 sec/Div.

VERIFY THAT:

THE FREQUENCY IS

25KHz 5%;

THE AMPLITUDE CH1 IS

560V 10%.

·

·

·

·

·

±

·

±

·

±

Содержание Superior Plasma 90 HF

Страница 7: ...SUPERIOR PLASMA 90 HF 7 General wiring diagram WIRING DIAGRAMS Wiring diagram input filter board...

Страница 8: ...SUPERIOR PLASMA 90 HF 8 Wiring diagram primary board power Wiring diagram primary board driver...

Страница 9: ...SUPERIOR PLASMA 90 HF Wiring diagram control board B Wiring diagram control board A 9...

Страница 10: ...SUPERIOR PLASMA 90 HF Wiring diagram control board D Wiring diagram control board C 10...

Страница 20: ...ILLUSTRATIONS SCREWS SCREW SCREWS TOP COVER SCREWS BOTTOM SCREWS 20 SUPERIOR PLASMA 90 HF SCREW SCREWS SCREWS...