WARNING:

WARNING

BEFORE PROCEEDING WITH REPAIRS TO THE

MACHINE READ THE INSTRUCTION MANUAL

CAREFULLY.

EXTRAORDINARY MAINTENANCE OPERATIONS

SHOULD BE CARRIED OUT ONLY AND EXCLUSIVELY

BY EXPERT OR SKILLED ELECTRICAL-MECHANICAL

PERSONNEL.

IF CHECKS ARE MADE INSIDETHE MACHINE WHILE IT

IS LIVE,THIS MAY CAUSE SERIOUS ELECTRIC SHOCK

DUE TO DIRECT CONTACT WITH LIVE PARTS AND/OR

INJURY DUE TO DIRECT CONTACT WITH MOVING

PARTS.

WARNING:

WIRING NEEDED FORTESTING

GENERAL REPAIR INSTRUCTIONS

TROUBLESHOOTING AND REMEDIES

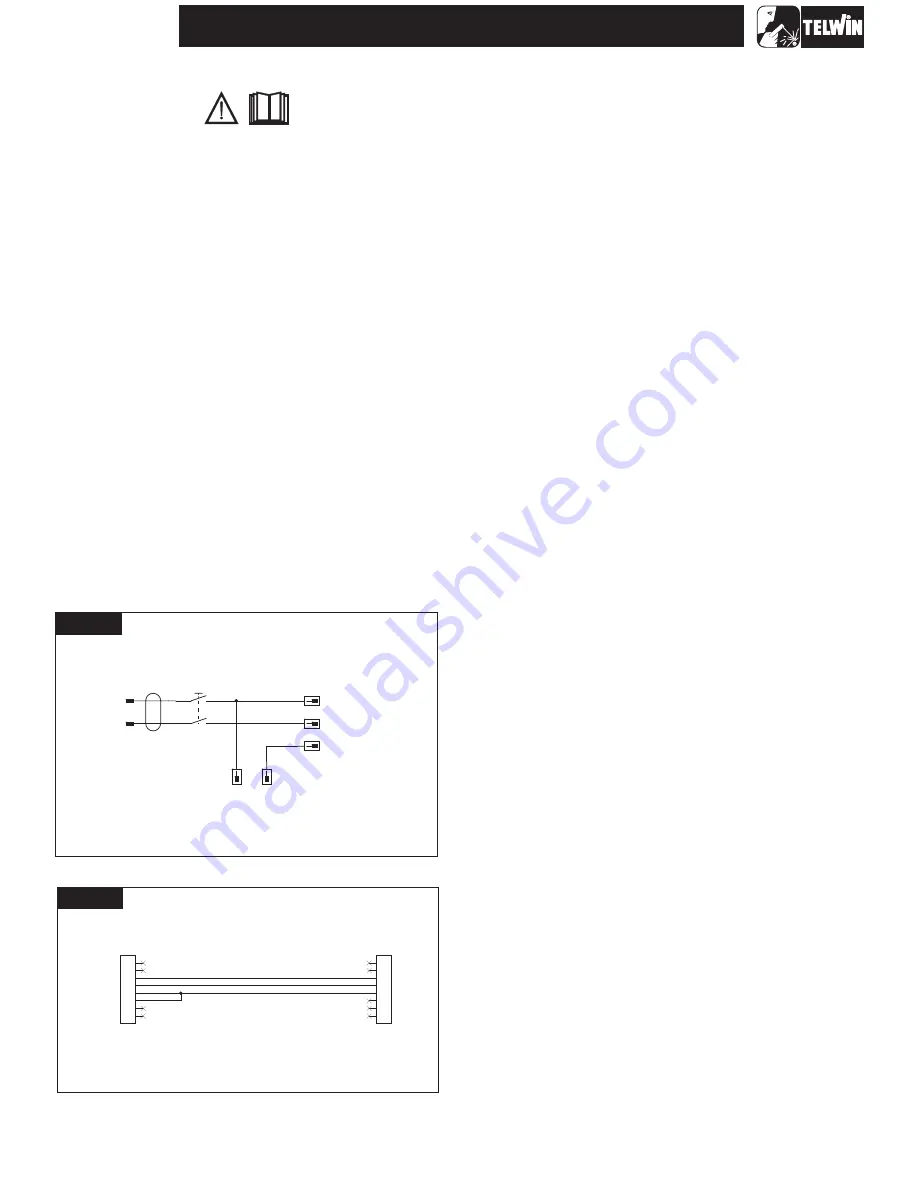

To carry out the low voltage tests on the machine, it is necessary to

use two special sets of test wiring that allow a 230Vac supply to

power the auxiliary transformer and by force some alarm signals

between the primary board and control board.

Follow the two electrical diagrams below to make the two sets of

wiring in figures A and B:

Every operation should be carried out in complete safety with the

power supply cable disconnected from the mains outlet.

-

undo the 12 screws fastening the 2 plastic shells (6 each) to the

front and back (

).

to extract the front plastic shell

it is necessary to disconnect all connectors on the control

board assembly. Fasten the control board assembly to the

metal front piece using its 4 screws and reconnect all the

connectors;

-

undo the 2 screws on the handle fastened to the top cover

(

;

-

undo the 14 screws fastening the top cover to the structure

(

);

-

pull gently outwards and slide out the top cover (

);

-

undo the 4 screws fastening the base to the structure (

);

-

separate the top metal structure from the base and place it on

the work bench.

the base should be removed if it is

necessary to reach the internal boards.

After completing the repairs, proceed in the reverse order to re-

assemble the machine and fasten the top cover and shells.

Using compressed air, carefully clean the power source

components since dirt is a danger to parts subjected to high

voltages and adversely affects the galvanic separation between

the primary and secondary boards.

It is important to be particularly

careful when cleaning the following parts:

Wiring for Aux Transf/Power supply/Aux Board

The following is a list of practical rules which must be strictly

adhered to if repairs are to be carried out correctly.

A) When handling the active electronic components, in particular

IGBT's and power DIODES, take elementary precautions for

electrostatic protection (such as wearing antistatic wristbands

or footwear, using antistatic working surfaces etc.).

B) To ensure the heat flow between the electronic components

and the dissipator, always place a thin layer of thermo-

conductive grease (e.g. COMPOUND GREASIL MS12)

between the contact zones.

C) The power resistors (should they require replacement) should

always be soldered at least 3 mm above the board.

D) If silicone is removed from some points on the boards it should

be re-applied.

N.B. Use only non-conducting neutral or oximic reticulating

silicones (e.g. DOW CORNING 7093). Otherwise, silicone that

is placed in contact with points at different potential (rheofores,

IGBT's etc.) should be left to reticulate before the machine is

tested.

E) The semiconductor devices should be soldered keeping below

the maximum temperature limits (usually 300°C for no more

than 10 seconds).

F) It is essential to take the greatest care at each disassembly

and assembly stage of the various machine parts.

G) Keep the small parts and other pieces that are dismantled from

the machine so as to be able to replace them in the reverse

order when re-assembling (damaged parts should never be

omitted but should be replaced, referring to the spare parts list

given at the end of this manual).

H) The boards (repaired when necessary) and the machine

wiring should never be modified without prior authorisation

from Telwin.

I)

For further information on machine specifications and

operation see the Instruction Manual.

1.0 Disassembling the machine

fig. 1A NOTE:

fig. 1A)

fig. 1B

fig.1B

fig. 1B

NOTE:

2.0 Cleaning inside the machine

To clean the electronic

boards we advise reducing the air pressure to prevent

damage to the components.

13

SUPERIOR PLASMA 90 HF

Figure B

JP5A

280373-1

1

2

3

4

5

6

7

8

JP5

280373-1

1

2

3

4

5

6

7

8

Figure A

230Vac

Alim.Aux

400V

Faston-M 6,3x0,8

SW1

Switch

0V

Faston-M 6,3x0,8

JP3B

Faston-M 6,3x0,8

L1

L2

230V

Faston-M 6,3x0,8

JP3A

Faston-M 6,3x0,8

Auxiliary transformer T3

Auxiliary power supply board

Auxiliary control wiring

Wiring auxiliary board side

Wiring control side

Содержание Superior Plasma 90 HF

Страница 7: ...SUPERIOR PLASMA 90 HF 7 General wiring diagram WIRING DIAGRAMS Wiring diagram input filter board...

Страница 8: ...SUPERIOR PLASMA 90 HF 8 Wiring diagram primary board power Wiring diagram primary board driver...

Страница 9: ...SUPERIOR PLASMA 90 HF Wiring diagram control board B Wiring diagram control board A 9...

Страница 10: ...SUPERIOR PLASMA 90 HF Wiring diagram control board D Wiring diagram control board C 10...

Страница 20: ...ILLUSTRATIONS SCREWS SCREW SCREWS TOP COVER SCREWS BOTTOM SCREWS 20 SUPERIOR PLASMA 90 HF SCREW SCREWS SCREWS...