Model KT14000 power casing tong maintenance and operation manual

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

4

3.3

Operation

3.3.1

Requirements for operators

(1)The operator should know the tong structure and the properties.

(2)Be familiar with the operation of hydraulic reversing handle on power tongs:

When manual reversing valve of control master tong is pushed, large gear on master tong turns in the

making-up tong direction; when manual reversing valve of control master tong is pulled, large gear on

master tong turns in the braking-out tong direction;

When manual reversing valve of control back tong is pushed, back tong is clamped; when manual

reversing valve of control back tong is pulled, back tong is released.

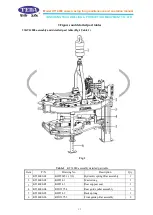

(3)Be familiar with the operation of shifting handle (various gears of shifting handle are shown in Fig.

below).

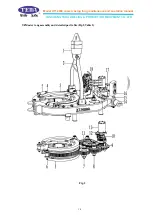

(4)Adjustment of safety door clearance

The clearance between safety door buckle and latch seat on the shell may be regulated through

adjusting

turning angle of eccentric shaft for minimum clearance for normal opening of safety door.

(5)Learn operation sequence and safety requirements;

(6)Be familiar with the instrument operation.

3.3.2

Operation of power tong

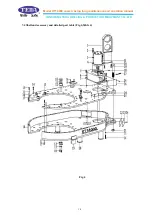

(1)Learn specifications of jaw plates and Die: each specification jaw plate of master tong and backup tong

have two jaw plates, and the two are same and may be installed on the left and right. During installing

jaw plate, it is necessary to check whether Die is worn or clean. It is necessary to tighten fixation bolts

of Die.

(2)Install jaw plate and Die with corresponding size for the string.

(3) Put shifting handle of the upper and lower shifting device on the neutral position;

(4)Start hydraulic power station;

(5)When hydraulic reversing handle is pushed or pulled, rotation noise of hydraulic motor should be heard

and open gear of tong head should not rotate;

(6)When shifting handle is put on any gear and hydraulic reversing

Note:

shifting should be carried out when hydraulic motor stops the rotation.

Содержание KT14000

Страница 1: ...MODEL KT14 000 CASING POWER TONG Ver 2017 Yancheng Teda Drilling and Production Equipment Co Ltd...

Страница 2: ......

Страница 4: ......