Model KT14000 power casing tong maintenance and operation manual

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

11

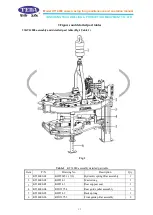

mount. The motor-valve assembly may then be lifted off.

4.5.2Disconnect & remove the linkage between the shifting handle and the shifting shaft.

4.5.3Back-off the shifting detent bolt (7/16

″

×2

″

). This relieves compression on the spring and allows the

ball to disengage from the groove in the shifting shaft. Remove the shifting detent bolt and, using

pencil magnets, extract the ball and spring before the shifting shaft is removed; this prevents loss of

the ball inside the tong.

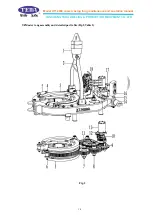

4.5.4Remove the doors. This is accomplished as follows:

(1)Remove the two door stop assemblies by removing the hexagon bolt 1/2

″

×1 1/2

″

(2)Remove the top lock nuts from the door roller shaft.

(3)Remove the grease fittings from the end of the door roller shafts and drive the shafts out. The shafts

should be very carefully driven out with a soft alloy material (e.g., brass rod, etc.) to eliminate the

possibility of damage to the shafts or door. This then allows the doors to be removed.

Note:

When removing the doors make careful note of the bearing shims which align the doors. At

reassemble of the doors after overhaul, it will still be necessary to reassemble door bearing

shims in the same sequence to assure desired door alignment.

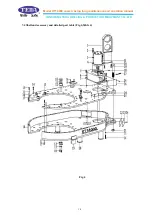

4.5.5The next step is to loosen the top and bottom brake band. This is accomplished by backing off the

brake band adjustment bolts until the nut is flush with the end of the bolt.

4.5.6With the bake bands loosened, the next stop is to remove the top and bottom cage plate. This is

accomplished by removing the three cage plate support bolts. With these three bolts removed, the top

cage plate can be lifted off.

Note:

Care should be taken in removing the cage plate bolts as they are the only means of support for the

bottom cage plate, after the brake band is loosened. To prevent damage to the bottom cage plate

or personal injury to the mechanic, it is recommended that the bottom cage plate be braced while

the mechanic removes the three cage plate bolts.

4.5.7Remove the lock nut and washer from the big idler gear assembly

,

small idler gear assembly,

centralizing roller assembly on the face plate. Remove the 3/8"×1-1/2" long hex head bolts from the

case body assembly.

4.5.8With all the above steps taken, the top tong plate can be lifted off providing access to the inside of the

gear case.

Содержание KT14000

Страница 1: ...MODEL KT14 000 CASING POWER TONG Ver 2017 Yancheng Teda Drilling and Production Equipment Co Ltd...

Страница 2: ......

Страница 4: ......