4 • MN02004

Issue/Rev. 0.3 (8/02)

Section 2 – Service (continued)

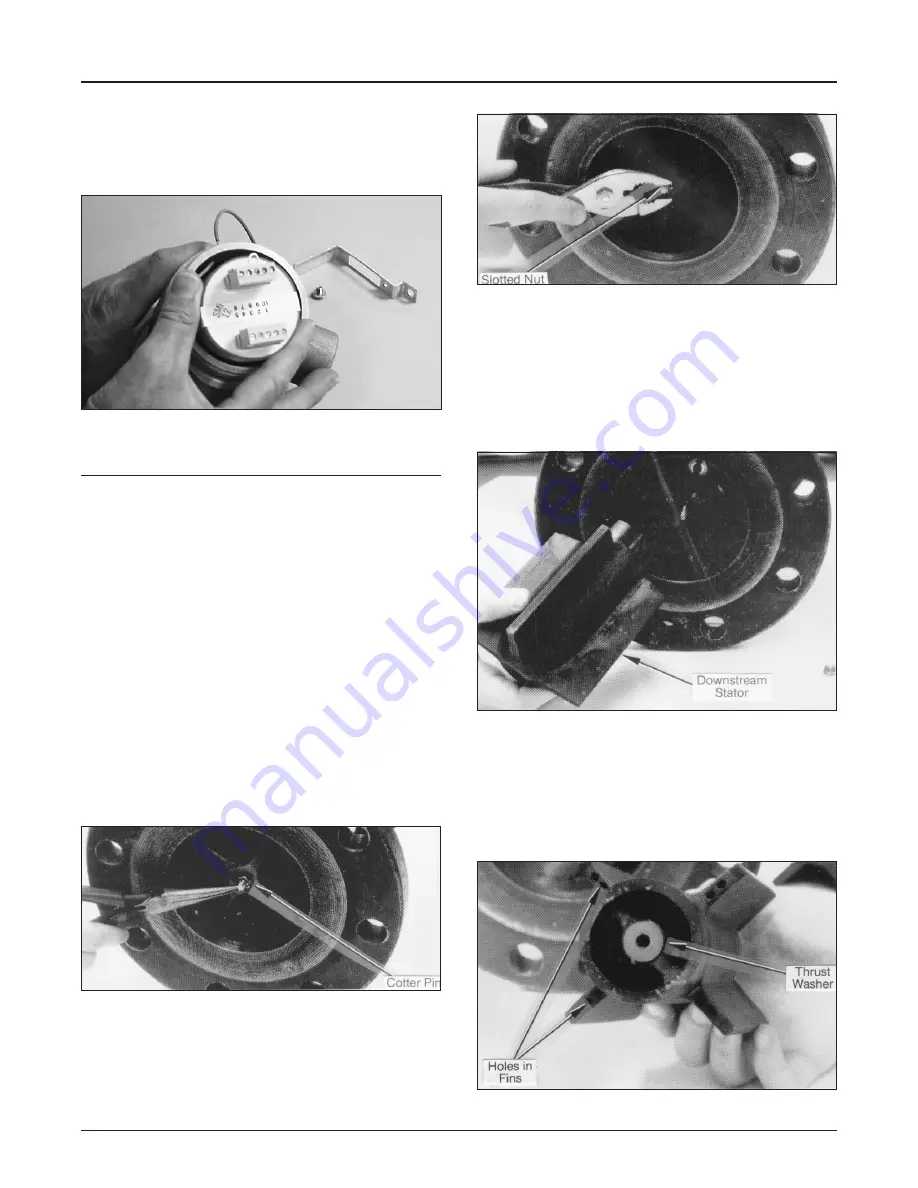

3. Disconnect output wiring and remove preamp from

junction box, Figure 6.

4. For reassembly, reverse procedures.

Figure 6

Removal and Servicing of Meter lnternals

1. Drain product from line. Drain in direction of flow

(if possible).

2. Make certain power has been disconnected to

meter.

3. Remove junction box cover, disconnect output

wiring and conduit where required.

4. Make certain meter is properly supported before

re-moving bolts and nuts.

5. With meter removed, check straightening

section to make certain tube bundle is clean

and free from damage.

6. If necessary to remove pick-up coil and

preamplifier, refer to procedures outlined above.

7. Remove cotter pin and slotted nut from

downstream end of meter, Figures 7 and 8.

Figure 7

Figure 8

8. Remove downstream stator, Figure 9. In a

unidirectional turbine meter, the stator is located

by a Woodruff key. Care should be taken that the

Woodruff key is not lost. In a bidirectional turbine

meter, there is no Woodruff key; the two stators

are located by two deflector rings.

Figure 9

9. Inspect the holes in the downstream stator fins

on the thrust bearing end, Figure 10, to make

certain they are open and the inside of the

stator is clean. Inspect thrust washer for signs

of roughness, grooves, or cracks.

Figure 10