•

Insert the circuit board into the upper locking point and

position it between it and the lower installation point

as far as it will go. Screw it down tight with 2 cross slot

screws:

•

Close the lid.

•

Check the function by pressing the push button.

•

Seal the calculator.

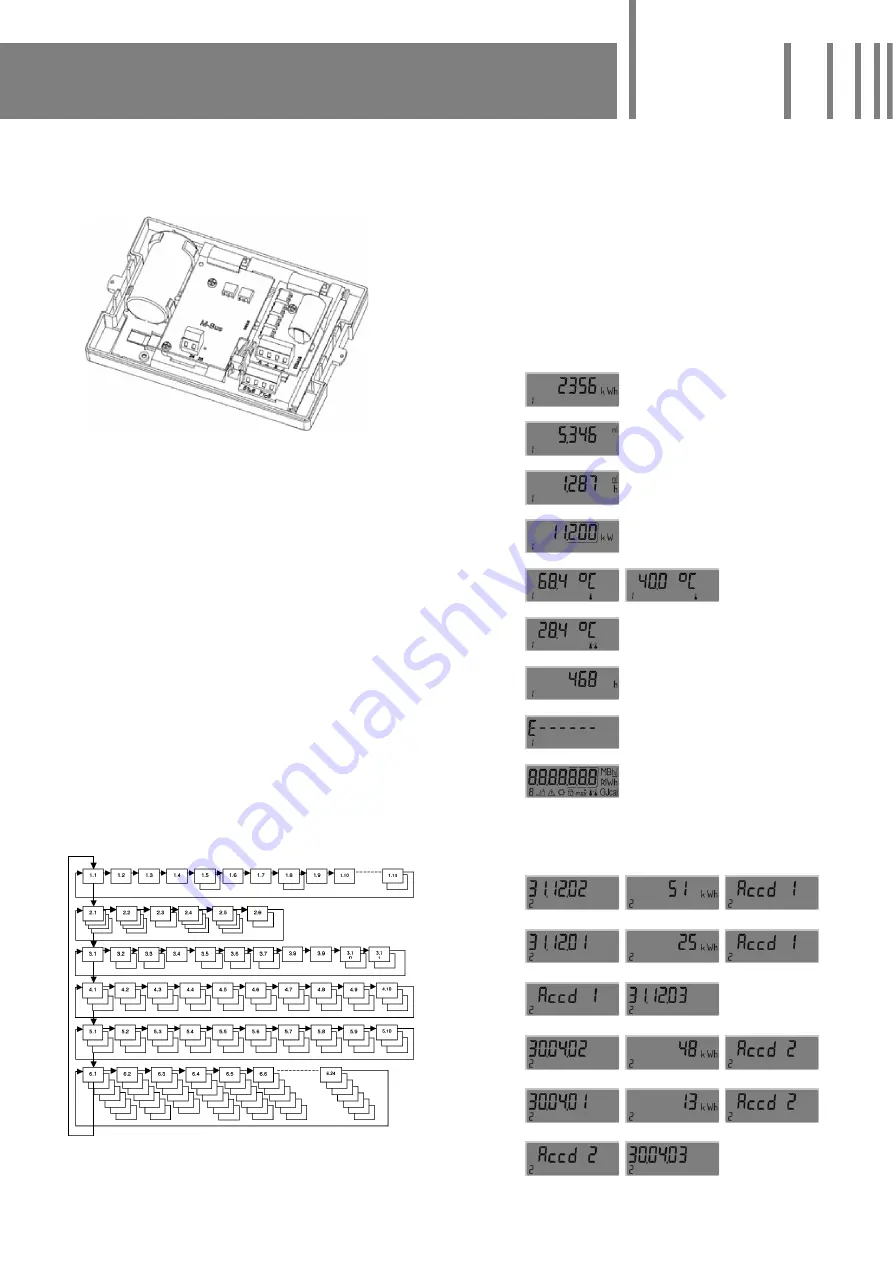

Operation

A push button is located on the meter‘s front panel. You can

use this button to switch between the individual displays.

In this case, we distinguish between pressing the button

quickly and pressing it for longer. If you press the button

quickly (< 3 seconds) switching takes place within a loop,

if you press for longer (> 3 seconds), it switches to the next

display loop. The „Energy“ window (sequence 1.1) for the

major loop is the basic display. If the button is not activated

for approx. 4 minutes, the meter automatically switches

the display off in order to save electricity. If the button is

pressed again, the meter reverts to the basic display. You

can use the HYDRO-SET software to program the loop

settings specifi cally for customers.

The heat meter has 6 display loops:

1 Major loop

2 Due date loop

3 Information loop

4 Pulse input loop

5 Tariff loop

6 Monthly loop

The loops are marked in the display with the numbers 1

to 6 in order to enable quick visual recording. The major

loop is programmed with the current data, e.g. for energy,

volume and fl ow. You cannot change the order of the data

available. Normally, loops 1-3 and 6 are active. As an opti-

on, you can add: the pulse input loop (4) when connecting

additional meters or the tariff loop (5) if making threshold

settings for monitoring the system.

Heat meter standard settings

The heat meter is works confi gured. This transforms the

read-off data to a preset „form“ and sets the readout win-

dows in the calculator. These settings can be changed using

the HYDRO-SET software.

Major loop

Sequence Window 1

Window 2

Window 3

1.1

Accumulated energy

1.2

Volume

1.3

Flow

1.4

Output

1.5

Flow temperature Return temperature

1.6

Differential temperature

1.7

Operating hours

1.8

Error code

1.9

Display test

Due date (DD) loop

Sequence Window 1

Window 2

Window 3

2.1

Due date 1 (DD 1)

DD 1 Energy „Accd

1“

2.2

DD 1 prev. year

DD 1 prev. year En. „Accd 1“

2.3

„Accd 1“

Future due date 1

2.4

Due date 2 (DD 2)

DD 2 Energy „Accd

2“

2.5

DD 2 prev. year

DD 2 prev. year En. „Accd 2“

2.6

„Accd 2“

Future due date 2