ENGLISH VERSION EM1-33038D

8. LOADING THE MEDIA

8-2

8. LOADING THE MEDIA

EM1-33039E

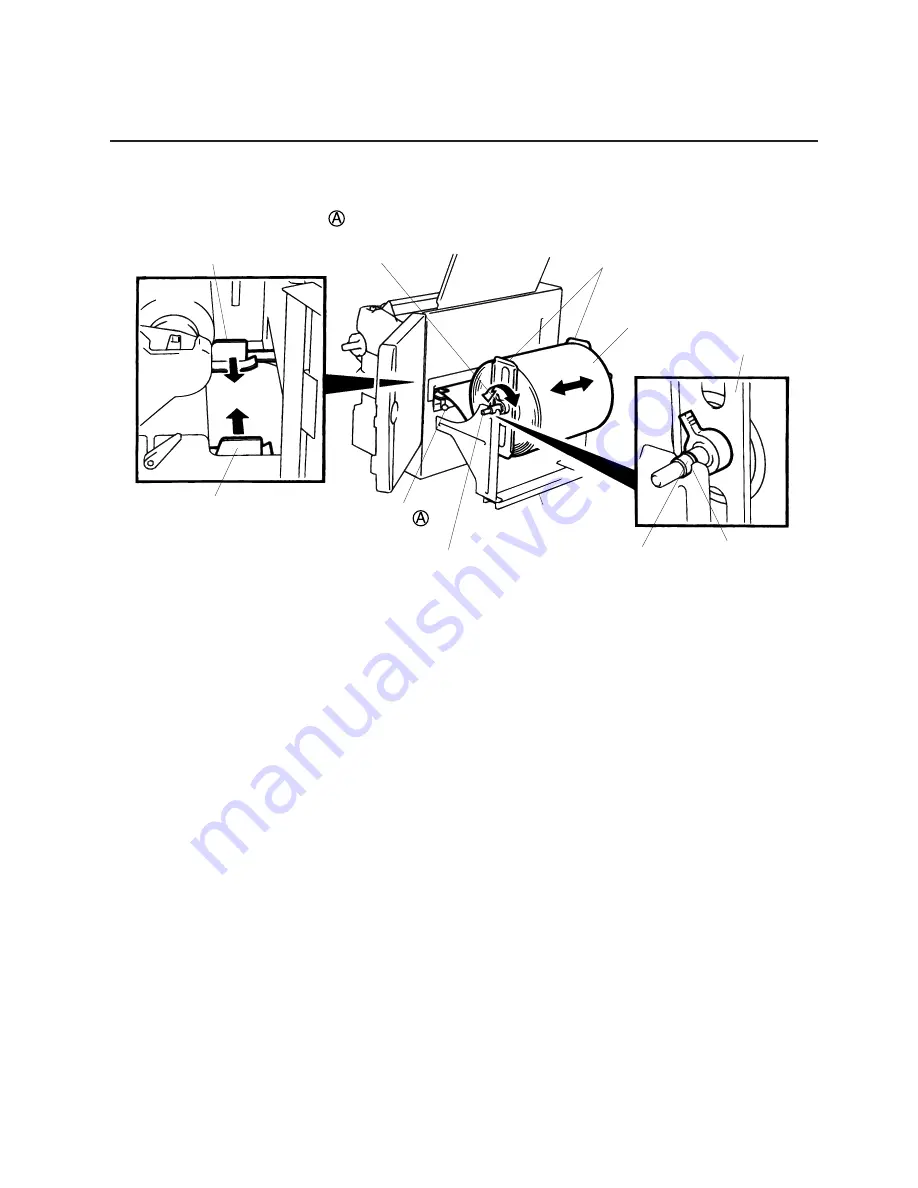

5.

Turn the Lock Levers of the Media Holders to the unlock position and readjust the Media position to

the center. Then lock the Media Holders securely with the Lock Levers. Fit the Media Guides to the

Media. Tighten the screw

firmly.

Media Guide

Holder Stand

Media Holder

Media Guide

Screw

Holder Shaft

Bush

Notch

Media Holder

Media

Fig. 8-3

NOTE: Set in the bushes of the Holder Shaft into notches of the Holder Stand securely.

6.

The black mark/feed gap sensor is selectable between the fixed type and the movable type by

changing the DIP switch (Refer to page 4-1). When the fixed type is selected, the black mark sensor

is located at the center of the media and the feed gap sensor is at 10 mm left to the black mark sensor.

The movable sensor can be located anywhere between the left end of the effective print width and

the fixed sensor.

After changing the sensor type, the sensitivity of the sensor must be adjusted. In this case call a

TOSHIBA TEC authorized service representative.

Lock Lever

Содержание TEC B-870 SERIES

Страница 1: ...TEC Thermal Printer B 870 SERIES Owner s Manual...

Страница 33: ......

Страница 34: ...PRINTED IN JAPAN EM1 33039E E...