TDI-Dynaload Division

WCL488 Series Water Cooled Electronic Loads

Operation & Programming Manual

402828, Rev. B1

Page 35

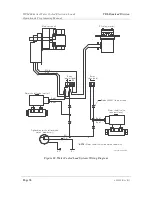

WCL488/WCS Water Cooled Load Systems

The WCL series of water-cooled loads can be provided in a fully configured rack assembly.

There are two standard sizes available: the full size rack measuring 60 inches tall, 22 inches wide

and 36 inches deep and our Mini-rack which measures 42 inches tall by 22 inches wide by 36

inches deep. The full size rack accommodates one WCL488 master with a maximum of nine

WCS slave units (up to 120kW) and the Mini-rack accommodates one WCL488 master and up to

four WCS slave units (up to 60kW).

Each of these rack assemblies provides all the necessary power connections and water

distribution needed for full operation. A system DC disconnect is provided as a functional

disconnect and is integrated into the protection circuitry of the system. All internal AC

distribution and master/slave interconnections are also provided. The power and water inputs are

conveniently located at the rear of the rack for simplified system integration. The flow of water

through the system is closely regulated in order to maintain the proper heat sink temperature and

eliminate the possibility of condensation.

The WCS electronic load system consists of a master control unit in conjunction with up to nine

(9) slave modules. The slave modules are dependent on the master to operate. Therefore, do not

attempt to operate the slave units without a master control unit.

The WCS System is designed to automatically detect the presence of the slave units. In operation,

the control display on the master will indicate the total system rating based on number of slave

units detected. The voltage and current ranges selected will also be taken into account and

reflected in the system rating. The user may choose to operate the system with any number of

slaves. When the AC power is applied to the slave, it becomes active in the system. If the slave is

not turned on the master will not detect it and will configure the system accordingly. There is no

requirement to sequence the use of slaves. A system will operate normally regardless of which

slave unit or units are selected.

Synchronized Paralleling

The synchronized paralleling function allows the user to connect one (1) or more slave units in

parallel. The master is controlled through normal operation; the slaves are connected via a twenty

five-pin ribbon cable. For systems assembled at the factory, this cable is provided. This cable

contains all the necessary signals for the slave to respond to the master unit. In all operating

modes, the master and all slaves will share the current in proportion to the selected current range.

IMPORTANT:

Master/slave operation is intended as an extension of the current and power

capabilities when testing a single output power source. The slave units

cannot be connected to a second source or output. This will cause damage

to any or all of the loads in the system.