TDI T

URBO

T

WIN

FROM

TECH DEVELOPMENT

Page 4

Publication T1-321

Issued November 15, 2013

recommended exhaust piping is installed. Consult your

TDI distributor for advice.

Exhaust piping should be routed downward to help

prevent any accumulation of condensation in the starter

motor.

If the overhung section of the starter is not otherwise

supported, TDI recommends that the exhaust piping be

supported with a suitable bracket(s).

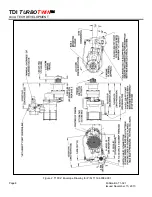

3.4 SOFT START VALVE & FILTER FITTING

The

“soft start” fitting

, by providing a slower opening

of the starter relay valve, eliminates excessive starter

pinion gear loading. The soft start fitting is identified by

P/N: 2-28243

found on its body. This fitting

MUST

be

installed at the starter relay valve as shown in figure 4. It

is screwed into the applied pressure (“IN” or “APP”) port

on the starter relay valve. There are currently no

approved substitutions for this fitting.

The

filter fitting

provides contamination protection to

the starter’s pre-engagement mechanism and the soft

start fitting installed downstream. The filter fitting is to be

installed on the “IN” port of the starter as shown in figure

4. It appears similar to the soft start fitting, however,

P/N: 2-28270

is found on its body.

CAUTION

For maximum pinion life and full warranty coverage,

the soft start valve (P/N: 2-28243) MUST be installed

in the applied pressure port (APP) of the relay valve.

WARNING

All pipes, fittings, flexible hose assemblies and

electrical harnesses are not to be used as a handle.

The starter is not to be used as a foot step.

Damage to pneumatic circuitry and/or starter can occur if

this warning is not heeded.

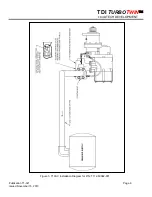

3.5 PIPING SYSTEM

Only type approved metallic hose assemblies are

approved in permanently pressurized compressed air

lines of starters. Non-metallic hose assemblies are

allowed only in case the piping system will be emptied

after the starting procedure.

Pipe unions must be type approved by GL. Downstream

of the pressure regulator a pressure relief valve should

be provided.

4.0 STARTER OPERATION

Prior to operation, check that all connections are tight

and free from leaks. Check the 1/4" NPT pipe plug or a

pressure gauge/transducer that may be connected to the

pressure port on the starter inlet.

WARNING

Do not operate the TDI

T

URBO

T

WIN

starter with air

pressure greater than the pressure rating on the

nameplate. This pressure is measured at the starter

inlet while the starter is running. The

T

URBO

T

WIN

starter

may only be operated in fully installed

condition.

The maximum operating pressure limit is the inlet

pressure measured at the starter’s inlet pressure check

port. To check the pressure, a 1/4"NPT pipe tap

connection is provided in the inlet housing to attach a

pressure gauge.

The static non-flowing supply pressure will always be

higher than the operating (dynamic) pressure. The

maximum pressure limit (proof pressure) that the

T100-V

starter housings may be subjected to is 600 PSIG (42

BAR). System pressure that exceeds the maximum

operating limit must use a pressure reducing device to

ensure that the operating pressure limit to the

T100-V

starter is maintained.

System static pressure that exceeds the 600 PSIG (42

BAR) limit must, in addition to pressure reducer devices,

incorporate a pressure relief valve set below 600 PSIG

(42 BAR) in the supply air line downstream of the

pressure regulator.

NOTE

For maximum life of the starter pinion and for the

protection of the engine ring gear, limit the operating

pressure to that necessary to start the engine at its most

difficult starting conditions.

All appropriate local pressure codes and pressure

limitations on other system components must be

adhered to and supersede the guidelines given in this

manual.

CAUTION

The operation of the starter may result in noise levels

exceeding 90 dBA. Protective hearing equipment

must be worn at all times.