HR150, 200; ER150, 200 FRESH AIR VENTILATION SYSTEMS

68-0269

8

Balancing Airflow

Balancing the airflow verifies that the Fresh Air Ventilation

System is delivering the intended airflow and energy

performance. Use the Airflow Balancing instructions in the

Installation section to check and balance the airflow.

Controls

Remote Override Switch Functions On/Off Control

If continuous ventilation is not required, an on/off control can

be used to activate the ventilator when it is switched to

Standby. Controls that can be used for this function include

dehumidistats, timers and wall switches. If moisture control in

bathrooms is a primary function of the system, a dehumidistat

can be used to switch the ventilator from a Low or Standby

setting to the High setting. Moisture removal throughout the

entire home can only be achieved when the outside air

contains less moisture than the inside air (typically during cold

weather conditions).

Digital Fan Timer

The ventilator controls are compatible with the Digital Fan

Timer. If more than one timer is activated, each runs

independently with the ventilator running at high speed until all

timers have timed out. Up to four timers can be installed in a

system. For complete instructions on the operation of the

Digital Fan Timer, refer to the instructions packed with the

timer.

Moisture Control

When a building is new, there is excess moisture in the wood,

plaster, cement and other construction materials. When the

new building is occupied, the activities of the occupants also

increase the moisture level. There can also be high levels of

formaldehyde and other chemicals that were used in the

building materials. Running the ventilation system on high

speed provides optimum indoor air pollutant reduction. High

speed also provides maximum moisture removal when the

outside air contains less moisture than the inside air.

(Typically during cold weather conditions.)

Operating Damper Frost Control

Some models have an electronically-controlled damper frost

control mechanism. When the outside temperature drops

below 27°F (-3°C), the defrost timer is activated. At the end of

the 17 minute run cycle, when the core can experience some

nominal frost buildup, the timer activates a motor-driven

damper door that simultaneously opens the defrost port and

closes off the supply air port.

INSTALLATION

When Installing this Product…

1.

Read these instructions carefully. Failure to follow these

instructions could damage the product or cause a haz-

ardous condition.

2.

Check the ratings on the product to make sure the prod-

uct is suitable for your application.

3.

Installer must be a trained, experienced service techni-

cian.

4.

After installation is complete, check out product opera-

tion as provided in these instructions.

CAUTION

Electrical Shock Hazard.

Can cause personal injury or equipment damage.

Disconnect power supply to prevent electrical shock or

equipment damage.

Unpacking Fresh Air Ventilation System

Check that all the components are included. The Fresh Air

Ventilation System is shipped assembled. The carton contains

the following:

• Fresh Air Ventilation System.

• Vibration isolation straps (4).

• Drain fittings (2) and T fitting (1).

• Literature package.

Except for the mounting hardware and drain fittings, the

ventilator is ready for installation. Wiring, drain connections

and ducting are required to complete the installation.

Mounting

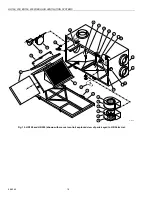

Suspended from Floor Joists

1.

Mount the four vibration isolation straps (provided) to

the side of the ventilator using the mounting screws

located on the cabinet. See Fig. 2 and 3.

2.

Securely fasten the other ends of the straps to the floor

joists with wide-head nails (not supplied), making sure

the unit is level. The straps are designed to reduce

noise, resonance or harmonics; therefore, using the full

length of the strap between the ventilator and the floor

joists is recommended.

NOTE: Removal of the door and core reduces the

weight of the ventilator, making it easier to lift

into place.

Floor Mounting

The mounting hardware included is not needed for floor

mounting.

1.

Use 2 x 4 in. wood pieces to build a frame to support the

ventilator along the bottom edge. The frame must hold

the ventilator at least 10 in. up from the floor to allow

clearance for the drain line.

2.

Set the frame back approximately 2 in. from the front-

edge to avoid interference with the hinged door.

3.

Place the ventilator on the frame. Secure the ventilator

to the frame using screws and a strip of wood or metal;

screw into the side walls of the ventilator within 1 in. of

the bottom.

4.

Connect the drain lines to a drain; see Installing Drain

Line and P-Trap section.

5.

Connect the ventilator to the ducts.

Installing Drain Line and P-Trap

There are two holes at the bottom of the ventilator for the

drain pan connectors.

1.

Insert the connectors through the hole in the drain pan

and the bottom of the unit.

2.

Place the washer and nut on the connector.

3.

Hand tighten the nut. See Fig. 9.