19

Models C708 & C716

Important: To the Operator

110817

Reset Mechanism

The reset button is located in the service panel on

the left side of the C708. The reset buttons are

located in the back panel of the C716. A reset button

protects the beater motor from an overload

condition. Should an overload occur, the reset

mechanism will trip. To properly reset the freezer

place the power switch in the OFF position. Press

the reset button firmly. Turn the power switch to the

ON position. Touch the WASH key

and observe

the freezer's performance.

WARNING: Do not use metal objects to

press the reset button.

Failure to comply may

result in severe personal injury or death.

If the beater motor is turning properly, touch the

WASH key

to cancel the cycle. Touch the AUTO

key

to resume normal operation. If the freezer

shuts down again, contact your authorized service

technician.

Air/Mix Pump Reset Mechanism

This reset button protects the pump from an

overload condition. Should an overload occur, the

reset mechanism will trip. To reset the pump, press

the reset button firmly.

WARNING: Do not use metal objects to

press the reset button.

Failure to comply may

result in severe personal injury or death.

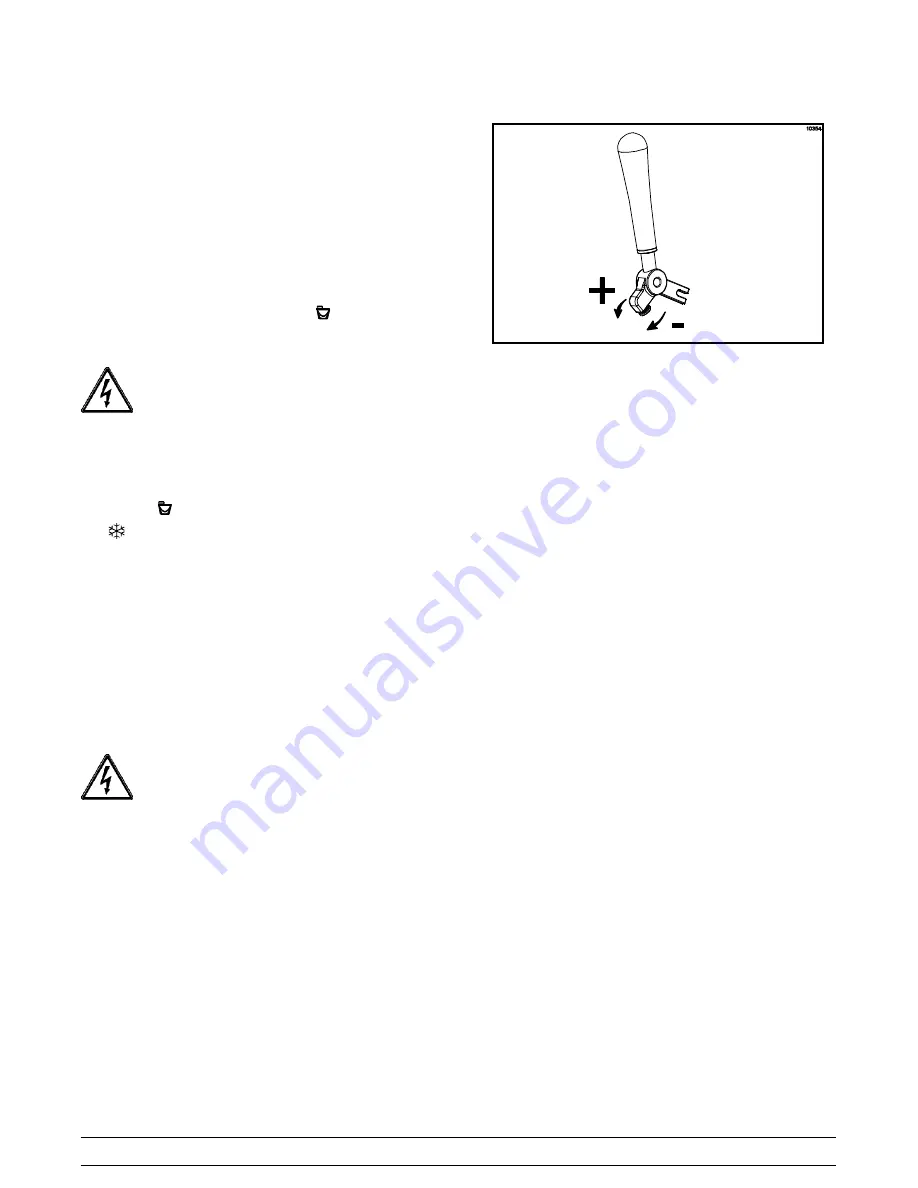

Adjustable Draw Handle

These units feature an adjustable draw handle(s) to

provide the best portion control, giving a better,

consistent quality to your product and controlling

costs. The draw handle(s) should be adjusted to

provide a flow rate of 5 to 7-1/2 oz. (142 to 213 g.)

of product by weight per 10 seconds. To INCREASE

the flow rate, turn the screw CLOCKWISE. To

DECREASE the flow rate, turn the screw

COUNTERCLOCKWISE . (See Figure 9.)

Figure 9

Operating Screen Descriptions

The fluorescent display located in the center of the

control panel is normally blank during the daily

operation of the machine. The display is activated

when the SEL key or the Manager's Menu is

selected. The display screen will also alert the

operator of specific faults detected by the control.

Note:

The displays illustrated in this section are

those seen on the Models C708. The Model C716

displays may vary slightly.

Power Up Memory (Initializing)

The seven segment display should display “00”

during the initializing sequence.

When the machine is powered, the control system

will initialize to perform a system check. The screen

will display “INITIALIZING”. There will be four types

of data the system will check: LANGUAGE,

SYSTEM DATA, CONFIG DATA, and LOCKOUT

DATA.

Language Initialization

The UVC platform supports multiple languages by

keeping specific strings in battery backed RAM.

After power-up or a CPU reset, the strings are

tested to see if the language strings are present and

not corrupted. If the strings are present and not

corrupted, initialization continues. Otherwise, the

operator is prompted to select a language. While

language strings are being checked for integrity, the

following screen is displayed.