23 - ENGLISH

•

Use the brush previously emerged in the sanitizer to thoroughly clean the drain duct

which connects the tank to the tap.

•

Never use any type of solvents and/or thinners to preserve the plastic parts and

gaskets during washing.

•

Chemical sanitizing products must be used in compliance with standards in force and

with the utmost caution.

•

During sanitizing operations, do not touch parts with tissues, sponges, rags or any

other non-sterile material.

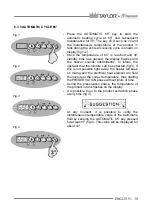

RINSING AND DRYING

•

Wash your hands well and/or wear disposable latex

gloves.

•

Remove from the sanitising tank all the components

which were previously disassembled, brushed and

immersed.

•

Rinse them with plenty of cold drinking water, making

sure to remove all possible leftover sanitising solution.

•

Place the rinsed components on a clean table and let

them dry in the air.

DO NOT use rags, sponges or anything else to dry the

components. Make sure no dust or other impurities

come into contact with the sanitized surfaces while

they are drying.

•

Also carefully rinse the fixed parts of the machine

which were treated with the sanitizing solution

(cylinder, drive shaft, etc.)

•

When all the components are dry, put them back onto

the machine, making sure the gaskets are in good

conditions.

Содержание Frigomat CH02 Series

Страница 1: ...MANUALE D USO E MANUTENZIONE OPERATING INSTRUCTION AND MAINTENANCE Serie Series CH02 05...

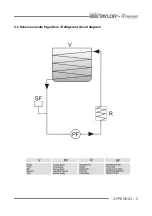

Страница 30: ...APPENDICI 2 9 2 Schema circuito frigorifero Refrigerant circuit diagram...

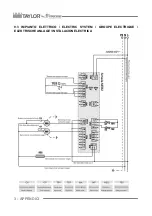

Страница 31: ...3 APPENDICI 9 3 IMPIANTO ELETTRICO ELECTRIC SYSTEM GROUPE ELECTRIQUE ELEKTRISCHE ANLAGE INSTALACION ELECTRICA...

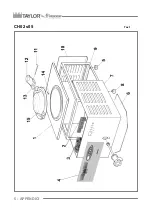

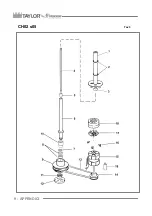

Страница 33: ...5 APPENDICI CH02 s05 Tav 1...

Страница 35: ...7 APPENDICI CH02 s05 Tav 2...

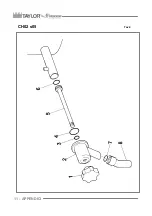

Страница 37: ...9 APPENDICI CH02 s05 Tav 3...

Страница 39: ...11 APPENDICI CH02 s05 Tav 4...

Страница 41: ...NOTE NOTES NOTES BEMERKUNG NOTA...

Страница 42: ......