1-2

TO THE INSTALLER

Model C300

To the Installer

1

CAUTION!

This unit must be installed on a

level surface to avoid the hazard of tipping. Extreme care

should be taken in moving this unit for any reason. Two

or more persons are required to safely move this unit.

Failure to comply may result in personal injury or damage

to the unit.

The authorized installer should inspect the unit for

damage and promptly report any damage to the local

authorized Taylor distributor.

This unit is made using USA sizes of hardware. All metric

conversions are approximate and vary in size.

Water-Cooled Refrigeration Units

(Water-Cooled Units Only)

On the back of the unit, two additional 3/8 in. (9.5 mm)

F.P.T. water connections for condenser inlet and outlet

have been provided for easy hookup. 3/8 in. (9.5 mm)

inside diameter water lines should be connected to the

machine. Flexible lines are recommended if local codes

permit. Failure to use adequately sized water lines may

cause the unit to go on high head pressure and shut

down.

Do not

install a hand shutoff valve on the out line. Water-

cooled units are counter flow and the water should flow in

this order: first through the automatic water valve;

second, through the inlet located at the bottom of the

condenser; third, through the outlet fitting located at the

top of the condenser

to an open trap drain.

Important!

Water pressures are pre-set at the factory.

Do not

adjust the water pressure

.

Improper water adjust-

ments may cause operation discrepancies.

IMPORTANT!

A backflow prevention device is

required on the incoming water connection side. Please

see the applicable national, state, and local codes for

determining the proper configuration.

Water Connections

An adequate cold water supply must be provided with a

hand shutoff valve. On the back of the unit, two 3/8 in.

(9.5 mm) male flare water connections have been

provided for easy hookup. A flexible line is recommended,

if local codes permit. A minimum of 25 psi. (172 kPa)

water pressure is required to avoid having the unit cut out

the low water pressure switch. A booster pump must be

provided if this pressure is not available.

Note:

Water lines beyond 200 ft. (61 m) require 1/2 in.

(13 mm) water lines.

IMPORTANT!

Install potable water connection

with a water filter and adequate backflow protection to

comply with applicable national, state, and local codes.

Water temperature is not to exceed 125°F (51°C). Water

pressure to the machine must be 55 to100 psi

(379 to 690 kPa).

It is always a good practice to have a filter system to

improve the quality of the water and to avoid clogging the

operating components.

Important!

The water filter (064422-SER) must be

thoroughly flushed with water before connecting it to the

machine. This removes any loose particles present from

the manufacture of the filter that could clog the flow

control. To flush the filter, connect the inlet end of the filter

to the water supply. Position the outlet end of the filter

over an empty pail. Open the water supply. Allow water to

flow through the filter until the water exiting the filter is

clear. Close the water supply. Attach the outlet end of the

filter to the machine. Reopen the water supply.

Figure 1-1

!

!

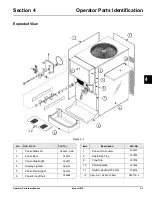

Содержание C300 NP

Страница 14: ...3 4 SAFETY Model C300 Safety 3 Notes...

Страница 18: ...4 4 OPERATOR PARTS IDENTIFICATION Model C300 Operator Parts Identification 4 Notes...

Страница 26: ...5 8 USER INTERFACE Model C300 User Interface 5 Notes...

Страница 40: ...6 14 OPERATING PROCEDURES Model C300 Operating Procedures 6 Notes...

Страница 42: ...7 2 OPERATOR CHECKLIST Model C300 Operator Checklist 7 Notes...

Страница 46: ...9 2 Model C300 Parts Replacement Schedule PARTS REPLACEMENT SCHEDULE 9 Notes...

Страница 52: ...LIMITED WARRANTY ON PARTS 11 4 Model C300 Limited Warranty on Parts 11 Notes...