P12

/19

IOM_FIH210201_HALIOS STD-PREM_EN

The technical data and performance may be modified

without prior notice depending on the technical advances.

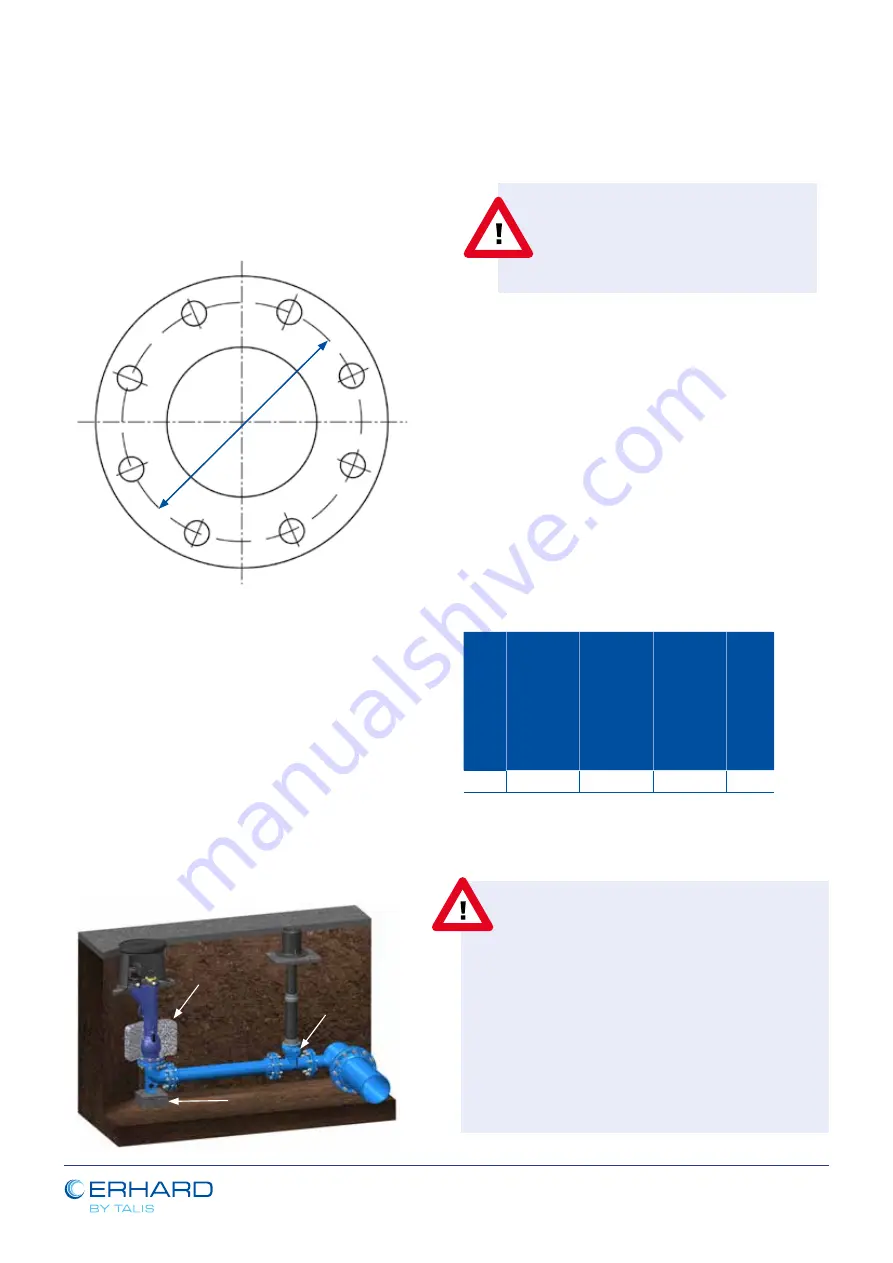

Draining area

Anchoring system of

the duck foot bend

Upstream

Isolating

valve

• Set up the bolts,

• Tighten them by hand,

• Tighten bolts gradually in a star-shaped pattern (see figure

6 – order from 1 to 8).

• At the end, tighten the connecting bolts evenly, without

distortion and crosswise, under a torque between 100 and

120 Nm. The value must not exceed 70% of the limit of

tightening torque of the bolts used.

Once the hydrant is assembled, the threads of the bolts/rods

should be greased with a brush or spray. MOLYCOTE or a similar

graphite based waterproof grease should be used to prevent

corrosion and facilitate subsequent dismantling operations.

After installation and before backfilling the trench and the

hydrant, perform a pressure test and functionality test (open and

close the hydrant) under pressure.

During backfilling of the hydrant, an adequate and sufficient

draining area must be established directly all around the hydrant

at the level of the two drainage devices, in order to allow the

emptying of its water volume. It may consist for example of an

adequate volume of pebbles, packed gravel, crushed rock or

any other appropriate means. When complete installation of

the hydrant is finished check that the drainage of the hydrant is

working perfectly by verifying that the hydrant empties after an

operation of opening/closing.

6 - COMMISSIONING

AND OPERATION

WARNING

Before installation, refer to technical

leaflet W331 from DVGW for deployment,

installation and implementation.

Before the hydrant is commissioned and installed, it must be

subject to a visual check. After installation, the hydrant must

be checked for movement of the inner valve: turn the square

cap over the total stroke (OPEN-CLOSE).

Each hydrant must be operated in respect of the operating

torque by a key according to DIN 3323-C.

Over-torque on the hydrant is strictly prohibited. According to

DIN standards, you will find in the table below the Maximum

Operating Torque (MOT) and Minimum Strength Torque (MST)

in Nm for gate underground fire hydrants to be operated by

key according to DIN 3323-C (see table 4). Operation by other

means or "Ring key and bar" is strictly prohibited.

Closing or opening operation of the hydrant must be done

under a torque that do not exceed the MOT stated in the table

below. In any case it is recommended to:

- turn 1/4 turn back after a complete opening operation,

- turn 1/4 turn back after a complete closing operation.

DN

Maximum

Operating

Torque (MOT)

according to

DIN EN14339

and DIN

EN1074-6

(in Nm)

Minimum

Strength

Torque (MST)

according to

DIN EN14339

and DIN

EN1074-6

(Nm)

Total number of

turns for

Opening or

Closing

(full stroke)

(Nm)

Number

of turns

before

flow

80

105

210

9

4

Table 4: Torques and number of turns

WARNING

Excessive torque may damage the hydrant body and

result in uncontrolled water leakage of up to 16 bar. In

this case, further work on the hydrant must be stopped

immediately and a safe distance to the hydrant must be

maintained, especially directly above the hydrant. The

isolating valve installed upstream of the hydrant must be

closed immediately in order to stop the supply of water.

If the torque necessary to close the hydrant is above

MOT values, plan a maintenance phase on the hydrant.

In case of over-torque applied to the hydrant, a proper

maintenance must be done including replacement of

the damaged components.

1

5

8

4

3

6

7

2

Figure 6: Flange DN80

Figure 7: Installation example